Your Trusted Partner for

Custom Industrial Valve Solutions

We provide end-to-end industrial valve solutions. From custom engineering and advanced manufacturing to global delivery. Your project’s success is our mission.

Our Strength in Numbers

Proven track record of excellence in industrial valve manufacturing

A Comprehensive Range of Industrial Valves

Engineered for performance and reliability across all major applications. Each valve is manufactured to exacting standards to ensure operational excellence. Find the right valve for your needs.

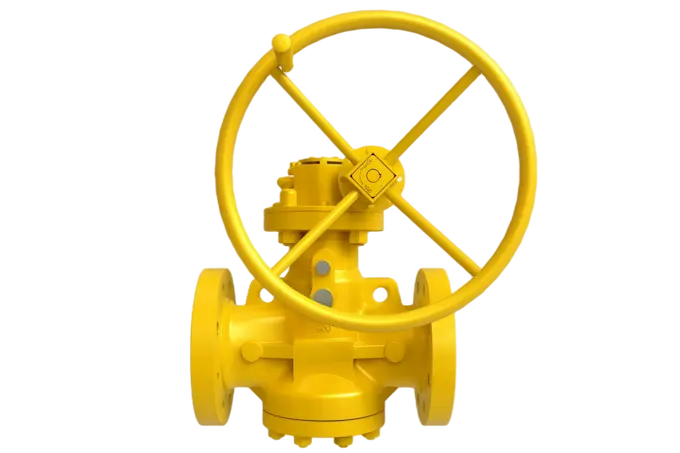

Trunnion Mounted Ball Valves

Trunnion Mounted Ball Valves

| Size | Pressure Rating | Material Grades | Trim |

|---|---|---|---|

| 2″ – 48″ | ANSI 150# – 2500# | A105N A351-316SS F51 Duplex |

ENP SS316 F51 Duplex |

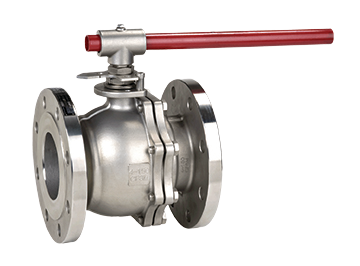

Floating Ball Valves

Floating Ball Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 1/4″ – 12″ | ANSI 150# – 600# 800WOG – 6000WOG |

WCB CF8M Alloy 20 Hastelloy C |

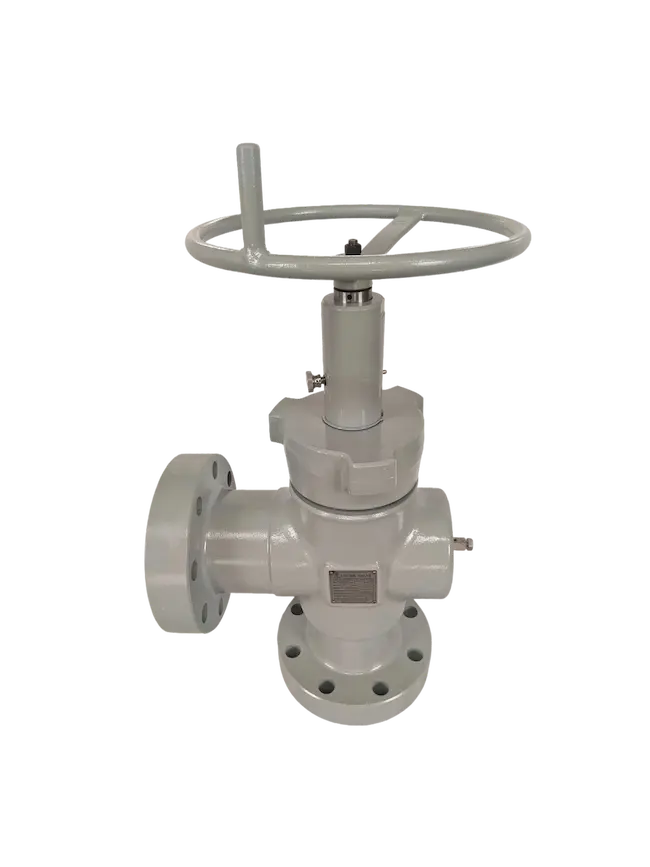

Gate Valves

Gate Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 1/4″ – 48″ | ANSI 150#-1500# 800# – 1500# |

WCB CF8M *Other Exotic Materials |

Globe Valves

Globe Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 1/4″ – 24″ | ANSI 150# – 1500# 800#-1500# |

WCB CF8M *Other Exotic Materials |

Check Valves

Check Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 1/4″ – 42″ | ANSI 150# – 2500# 800# – 1500# |

WCB CF8M *Other Exotic Materials |

API 6A Valves

API 6A Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 1″ – 4″ | 2000 – 15000 PSI | AISI 4130 AISI 8630 Inconel 625 |

Plug Valves

Plug Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 2″ – 24″ | ANSI 150# – 1500# | WCC LCC |

Welded Body Trunnion Ball Valve

Welded Body Trunnion Ball Valve

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 2″ – 48″ | ANSI 150# – 2500# | A350-LF2 & LF6 F51 DUPLEX |

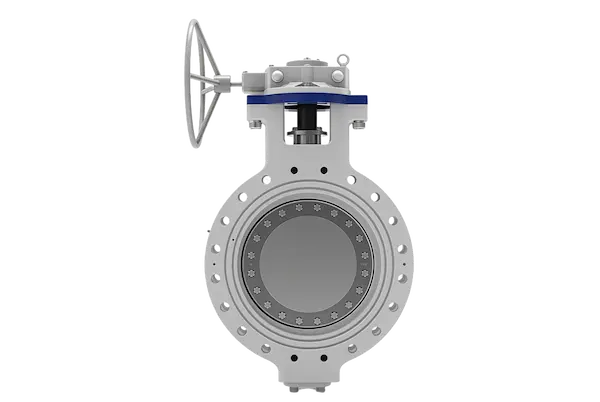

Butterfly Valves

Butterfly Valves

| Size | Pressure Rating | Material Grades |

|---|---|---|

| 2″ – 48″ | ANSI 150# – 600# | WCB CF8M Duplex Steel |

Industries We Serve

For over 15 years, YINKE Valve has been focused on servicing critical industrial markets worldwide. We manufacture high-quality certified valves designed to meet stringent industry standards across multiple sectors.

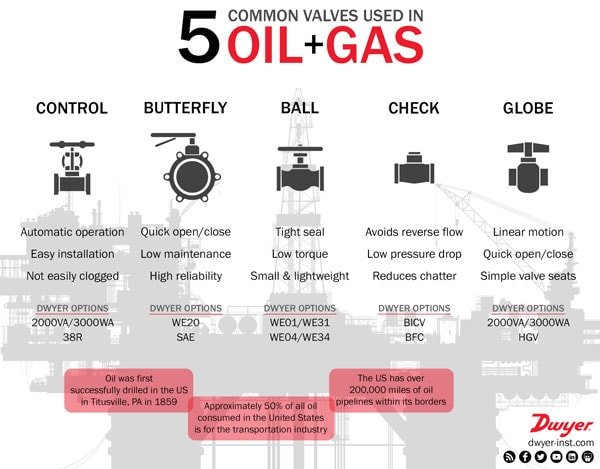

Oil & Gas

Upstream, midstream, and downstream applications including refineries, petrochemical plants, and pipeline systems.

- • Wellhead & Christmas Tree Valves

- • Pipeline Ball & Gate Valves

- • Refinery Process Valves

- • Emergency Shutdown Valves

Chemical Processing

Corrosion-resistant valves for harsh chemical environments and specialty applications.

- • Exotic Material Valves

- • High-Temperature Applications

- • Corrosive Media Handling

- • Process Control Valves

Power Generation

Critical service valves for thermal, nuclear, and renewable energy power plants.

- • Steam Service Valves

- • Feedwater System Valves

- • Nuclear Grade Valves

- • Boiler & Turbine Valves

Water & Wastewater

Reliable valve solutions for municipal water treatment and distribution systems.

- • Water Treatment Valves

- • Distribution System Valves

- • Sewage Treatment Valves

- • Desalination Plant Valves

Technical Resources & Downloads

Access comprehensive technical documentation, product catalogs, and engineering resources to support your valve selection and specification process.

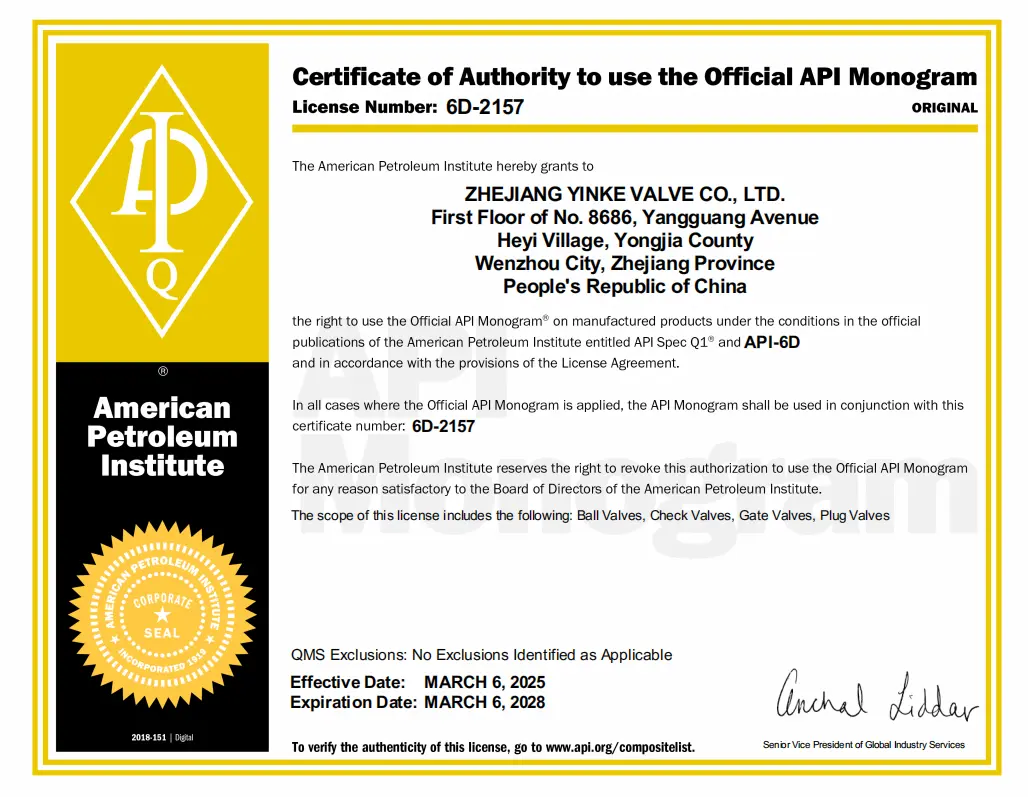

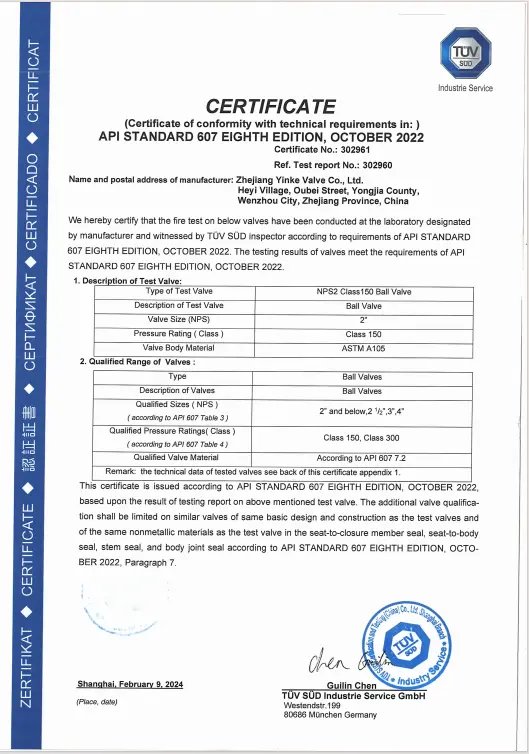

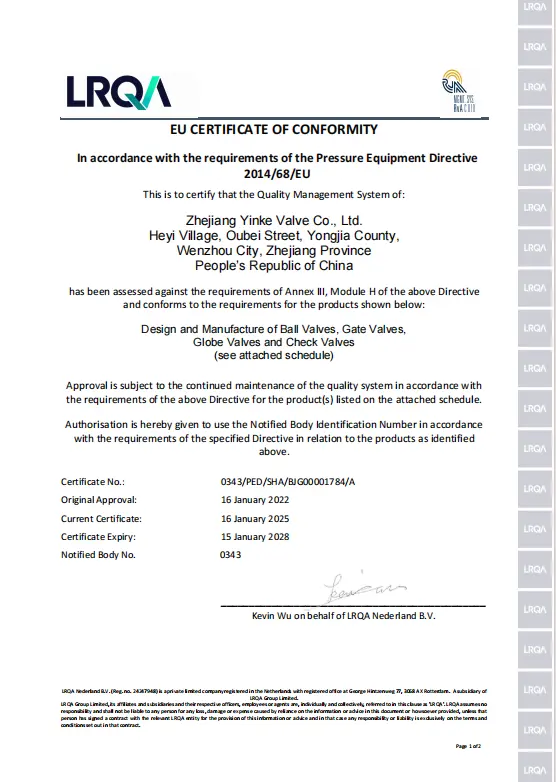

Quality Certifications & Standards

Our commitment to quality is validated by international certifications and adherence to global industry standards.

API 6D Certification

Pipeline valve specification for oil and gas industry applications

API 607 Fire-Safe

Fire-safe qualification testing for quarter-turn valves for oil and gas

CE Certification

European Conformity marking for product safety and compliance

Where Precision Engineering Comes to Life

Our 20,000 m² state-of-the-art facility is the heart of our operation. Here, advanced CNC automation and a culture of precision merge to deliver superior quality with exceptional efficiency.

What Our Customers Say

Hear from industry professionals who trust YINKE VALVE for their most critical applications.

“YINKE VALVE delivered exactly what we needed for our high-pressure steam application. Their custom engineering approach and quality exceeded our expectations. The 18-month warranty gave us confidence in their product.”

“Outstanding service from initial consultation through delivery. Their team understood our requirements perfectly and provided a cost-effective solution that has been performing flawlessly for over two years.”

“We’ve been working with YINKE for several projects now. Their manufacturing quality is consistently excellent, and their technical support team is always available when we need them. Highly recommended.”

Trusted by Industry Leaders Worldwide

Our partnerships with Fortune 500 companies and leading industrial organizations demonstrate our commitment to excellence and reliability in valve manufacturing. These strategic relationships drive innovation and ensure we deliver world-class solutions.

Join the ranks of industry leaders who trust our expertise for their critical valve applications

Become Our Partner

More Than a Supplier. We Are Your Solution Partner.

Tailored Engineering

Your unique challenge is our design blueprint. We deliver full OEM/ODM solutions engineered to your precise specifications.

One-Stop Project Management

From initial consultation to final delivery and support, your project is streamlined under one expert team.

Uncompromising Quality Assurance

Our facilities are governed by global standards. Every valve is rigorously tested to guarantee zero-defect performance.

Advanced Manufacturing Power

Our 20,000m² facility and 5 production lines give us full control over quality, lead times, and large-scale order fulfillment.

Technical Insights & Industry News

Stay informed with the latest valve technology developments, industry trends, and application case studies from our technical experts.

Understanding API 6D Standards for Pipeline Valves

Comprehensive guide to API 6D certification requirements, testing procedures, and compliance standards for pipeline valve applications.

Read More →

Valve Preservation Strategies for Long-Term Storage

Essential preservation techniques to maintain valve integrity during storage and ensure optimal performance upon installation.

Read More →

Material Selection for Chemical Processing Applications

Case study examining exotic material selection criteria for valves in corrosive chemical processing environments.

Read More →Ready to Discuss Your Valve Requirements?

Our team of valve experts is standing by to support your project. Contact us today for a detailed technical consultation and a no-obligation quote. Your challenges are our opportunities.