Floating Ball Valve – Design, Applications & Comparison

Floating ball valves provide a simple, effective solution for isolating fluid flow. They seal tightly, operate with a quarter turn, and work under a range of pressures, temperatures, and media. Engineers choose floating ball valves from China for clean fluids, gas services, utility lines, and typical process tasks because they are reliable, compact, offer good flow control, and are cost-effective. The design is smart. The ball is not fixed on bearings; instead, line pressure pushes it against a downstream seat to form a seal. This slight movement is the key mechanism, delivering functionality with few components.

Our Product Categories

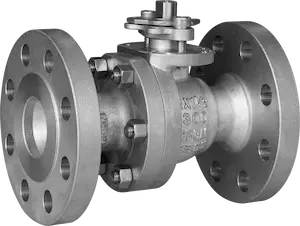

API 6D Floating Ball Valve

Premium quality valves designed to meet API 6D standards for pipeline applications with superior performance and reliability.

Stainless Steel Floating Ball Valve

Corrosion-resistant stainless steel construction ideal for chemical processing and aggressive media applications.

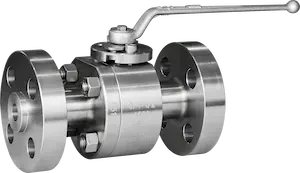

Flanged Floating Ball Valve

Flanged end connections for easy installation and maintenance in various industrial piping systems.

What Is a Floating Ball Valve?

A floating ball valve is a quarter-turn valve where the ball rests on the seats and stem rather than on trunnions or bearings. In the closed position, differential pressure shifts the ball toward the downstream seat, creating a tight seal with a compact design.

Key Elements of a Floating Ball Valve

- Body construction: Available as one-piece, two-piece split body, or three-piece for easier maintenance.

- Ball: Offered in full port or reduced port designs, precision-machined and polished.

- Seats: Made of soft materials like PTFE, RPTFE, PEEK, Nylon, Devlon or metal-seated for demanding applications.

- Stem: Configured with blowout-proof arrangements and live-loaded packing.

- Sealing: Utilizes body gaskets, stem packing, and anti-static paths.

- End connections: Options include threaded, socket weld, butt weld, or flanged.

- Actuation: Can be operated manually via a lever, with a gear operator, or automatically through an integrated mounting pad.

How Sealing Works

- When closed, line pressure pushes the ball downstream to load the downstream seat.

- A light preload may be applied by the upstream seat depending on the design.

- Many designs seal in both directions, with some featuring a cavity relief hole to allow trapped pressure to escape to the upstream side.

Where This Design Shines

- Provides tight shutoff with few moving parts.

- Compact size and lower weight compared to trunnion designs.

- Quick operation suited for on/off duties.

- Economical choice for small to medium sizes with effective performance.

Limits to Keep in Mind

- Torque increases rapidly with size and pressure because the ball must shift against the seat.

- Large sizes or high differential pressures may be better served by a trunnion-mounted design.

- In services with slurries or abrasive solids, soft seats may erode unless upgraded with metal seating or hard coatings.

FLOATING BALL VALVE MANUFACTURER

As a dedicated manufacturer of floating ball valves, our team supplies high-quality solutions for multiple industries. Our valves are built to international standards like API 6D and MSS-SP-110 for consistent performance and a long service life.

We recognize the floating ball valve’s role in controlling flow and ensuring safety in critical applications. Our valves undergo strict quality control and testing at every production step. Our advanced manufacturing methods and experienced engineers allow us to produce valves that meet each project’s specific requirements.

Our products are used in oil and gas, chemical processing, power generation, and water treatment. We offer a full range of sizes, materials, and configurations to match various operating conditions. By choosing our valve solutions, you gain technical expertise, responsive customer support, and a solid commitment to innovation.

Contact our team today to learn more about our floating ball valve offerings and discuss your next project.

Technical Specifications

| Specification | Details |

|---|---|

| Design Standards | API 6D, MSS-SP-110, ASME B16.34 |

| Size Range | 1/2″ to 24″ (DN15 to DN600) |

| Pressure Class | ASME Class 150, 300, 600, 900, 1500 |

| Body Materials | Carbon Steel, Stainless Steel (316/304), Duplex, Super Duplex |

| Seat Materials | PTFE, RPTFE, PEEK, Nylon, Devlon, Metal Seated |

| Temperature Range | -46°C to +200°C (PTFE) / -196°C to +550°C (Metal Seated) |

| End Connections | Threaded, Socket Weld, Butt Weld, Flanged |

| Operation | Manual Lever, Gear Operator, Pneumatic, Electric, Hydraulic |

| Fire Safe | API 607, ISO 10497 certified options available |

| Testing Standards | API 598, API 6D, ISO 5208 |

Key Design Features and Standards

Popular Standards

- • API 6D details design, materials, pressure testing, marking, definitions for DBB and DIB, and operational requirements for pipeline service.

- • MSS-SP-110 is common for compact ball valves used on plants and skids.

Other Standards

Standards such as ASME B16.34, ASME B16.5, ASME B16.10, API 598, and ISO 10497 are also referenced in floating ball valve design.

Design Features to Look For

Blowout-Proof Stem

Built-in shoulder design prevents stem expulsion under pressure for enhanced safety.

Anti-Static Device

Metallic path reduces static buildup in dry gas services for operational safety.

Fire-Safe Construction

Secondary graphite sealing maintains shutoff capability after fire exposure.

Bubble-Tight Sealing

Precision machined ball and seats ensure zero leakage performance.

Quarter-Turn Operation

90-degree rotation for quick open/close operation with minimal torque.

Bidirectional Flow

Effective sealing in both flow directions with cavity relief capability.

Applications and Industries

Common Applications

- Natural gas distribution and plant utilities

- Refinery units and petrochemical skids

- Chemical processing and solvent handling

- Water treatment and reverse osmosis systems

- HVAC and thermal fluid systems

Industry Sectors

Oil & Gas

Chemical

Power Generation

Water Treatment

Floating vs. Trunnion Ball Valve Comparison

| Attribute | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Ball Support | Supported by seats and stem | Supported by trunnions or bearings |

| Seat Energization | Line pressure moves ball onto downstream seat | Spring-loaded seats press onto fixed ball |

| Typical Size Range | Common up to NPS 6-8 | Used from NPS 6 to NPS 24 or more |

| Torque Behavior | Increases with pressure and size | More stable with lower torque at larger sizes |

| Cost and Weight | Lower cost and weight in small-medium sizes | Higher initial cost but longer lifecycle |

| Best Applications | Utilities, general process, compact systems | Pipelines, high pressure, large diameters |

Technical Documentation

Technical Brochure

Complete technical specifications and features guide

Sample Drawing

Detailed dimensional drawings and installation guides

Frequently Asked Questions

Q: What makes a floating ball valve “floating”?

A: The ball rests on the seats and stem, shifting slightly under line pressure to load the downstream seat.

Q: Are floating ball valves bidirectional?

A: Many models are bidirectional and include a cavity relief hole to face upstream.

Q: When should I select a trunnion ball valve instead?

A: Trunnion valves are better for larger sizes, high differential pressures, or frequent cycling.

Q: How do API 6D and MSS-SP-110 relate to floating ball valves?

A: API 6D sets requirements for pipeline-grade valves, while MSS-SP-110 is used for compact valves in plant service.

Q: What is the difference between full port and reduced port?

A: Full port maintains a bore close to the pipe’s internal diameter, while reduced port increases flow velocity and pressure drop through the valve.

Get In Touch With Our Experts

Contact our team today to learn more about our floating ball valve offerings and discuss your next project.