Premium IndustrialStainless Steel Valves

Engineered Excellence in CF8M (316) & CF8 (304) for Critical Applications in Oil & Gas, Petrochemical, and Chemical Processing Industries

Comprehensive Stainless Steel Valve Portfolio

Precision-engineered valves in CF8/SS304, CF8M/SS316, CF3/SS304L, and CF3M/SS316L configurations for demanding industrial applications

Gate Valves

Full-bore design with rising stem construction. Available in CF8/CF8M materials for excellent shutoff performance in pipeline applications.

Ball Valves

Quarter-turn operation with floating or trunnion-mounted design. CF8M construction for superior corrosion resistance in aggressive media.

Globe Valves

Precise flow control with excellent throttling characteristics. Y-pattern and straight-through designs in CF8/CF8M materials.

Check Valves

Swing and lift-type designs for preventing backflow. CF8M construction ensures reliable operation in corrosive environments.

Butterfly Valves

Lightweight, quarter-turn operation with wafer and lug designs. CF8/CF8M disc and body for chemical processing applications.

Plug Valves

Quarter-turn operation with lubricated and non-lubricated designs. CF8M construction for reliable shutoff in harsh conditions.

Material Engineering Excellence

Comprehensive comparison of stainless steel grades for optimal material selection in corrosive service applications

CF8 (SS304)

General Purpose Stainless Steel

Chemical Composition (wt%)

Cr: 18-21% | Ni: 8-11% | Mo: ≤0.5% (typically 0)

CF8M (SS316)

Superior Corrosion Resistance

Chemical Composition (wt%)

Cr: 18-21% | Ni: 9-12% | Mo: 2.0-3.0%

Critical Industry Applications

Proven performance across demanding industrial sectors with specialized material recommendations

Oil & Gas

Produced water, chloride-bearing fluids, offshore topsides

Petrochemical

Acids, solvents, CIP media processing

Water Treatment

Brine, RO, SWRO desalination systems

Power Generation

Condensate, cooling water, auxiliary systems

Marine/Offshore

Seawater exposure and spray applications

Chemical Processing

Aggressive chemicals, high-purity applications

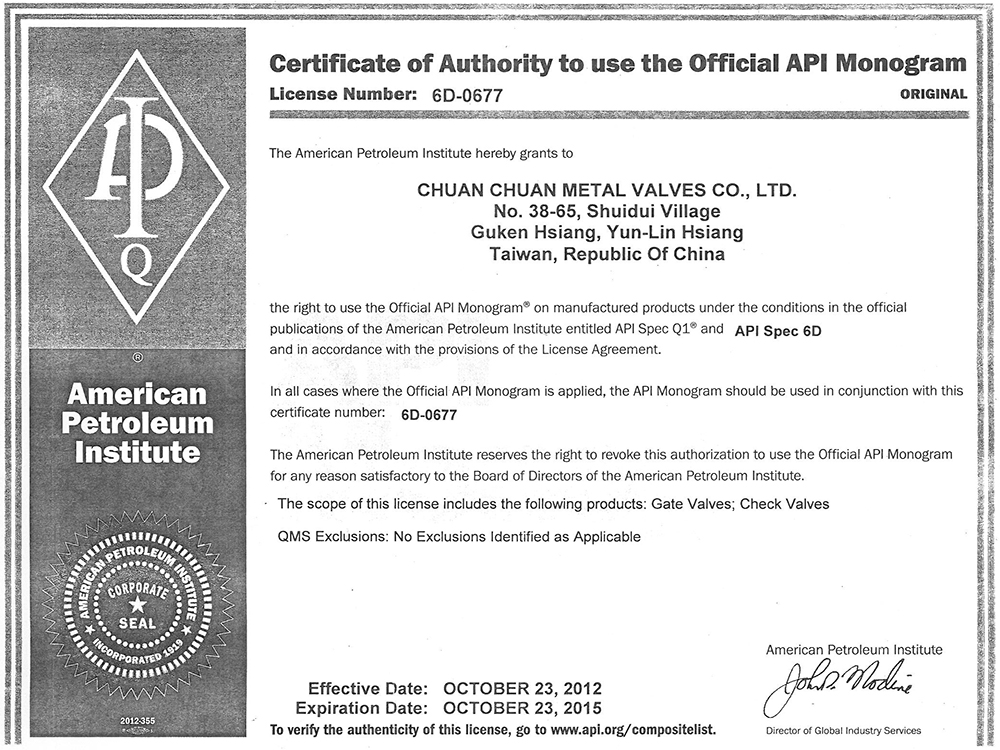

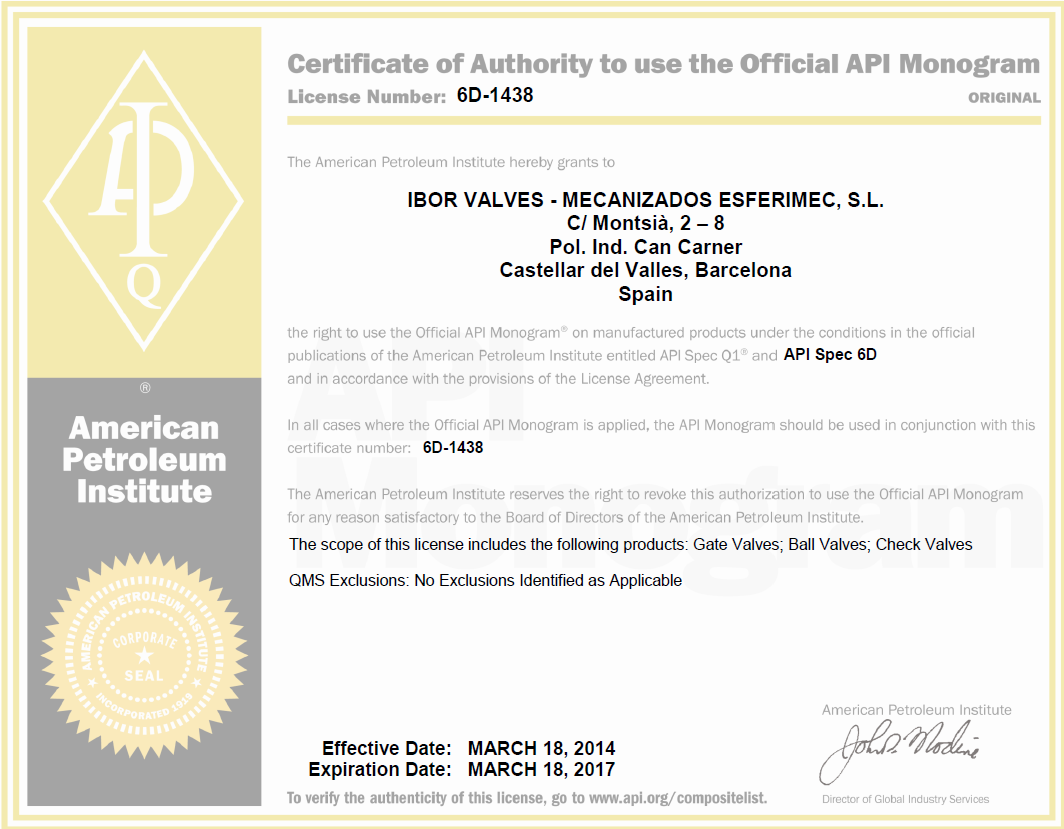

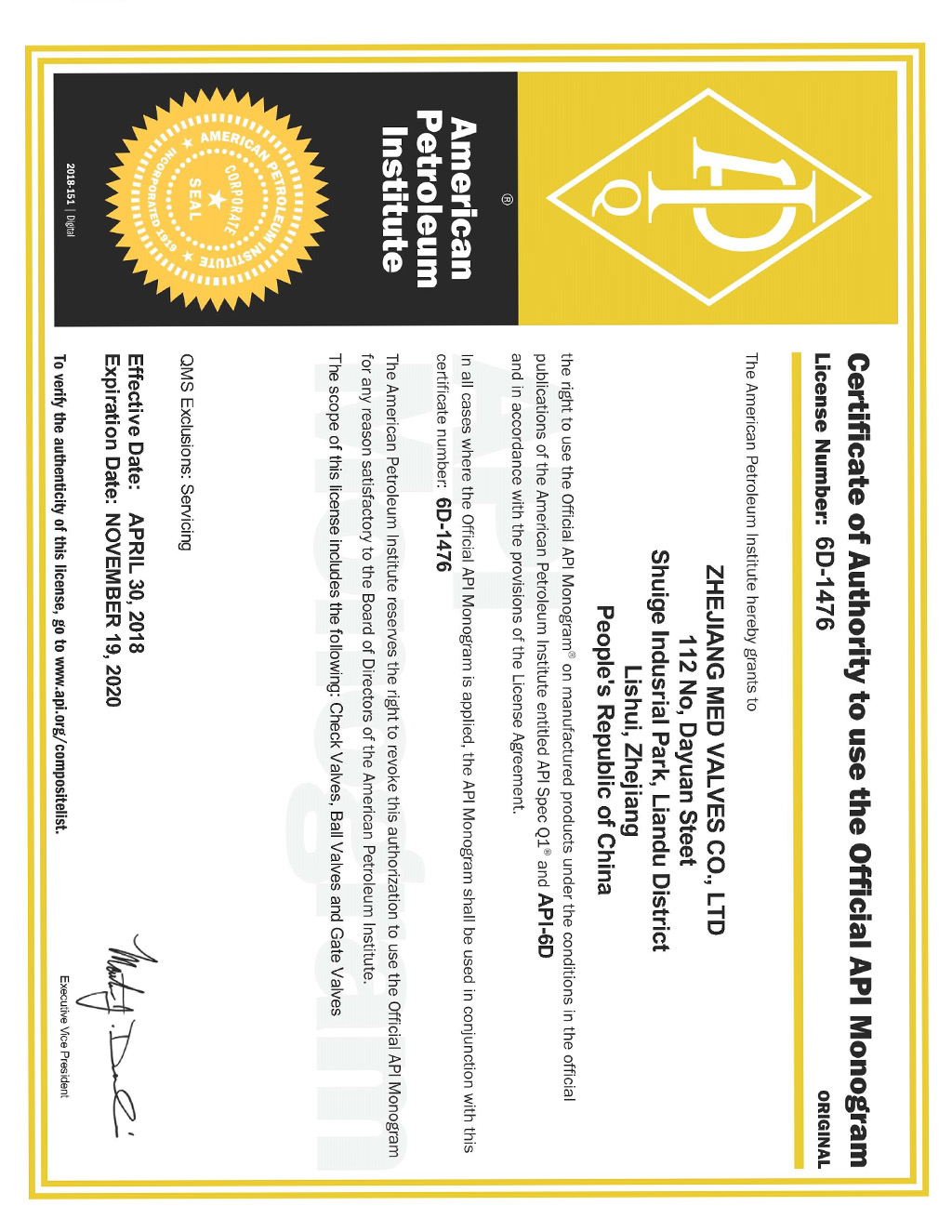

Global Quality Certifications

Certified compliance with international standards ensuring reliability and performance

API 6D Certification

Pipeline valve specification for oil and gas industry applications with monogram license verification.

API 607 Fire-Safe

Fire-safe qualification testing for quarter-turn valves ensuring safety in emergency conditions.

CE Certification

European Conformity marking ensuring product safety and compliance with EU standards.

ISO 9001:2015

International quality management system standard for consistent manufacturing excellence.

API 6FA Fire-Safe

Fire-safe testing requirements for rising stem valves with comprehensive safety validation.

ISO 5208 Testing

Industrial valve pressure testing standards ensuring leak-tight performance and reliability.

Advanced Manufacturing Capabilities

State-of-the-art facility with precision CNC equipment and comprehensive quality control systems

Production Lines

Advanced CNC machining centers with automated quality control for consistent precision manufacturing.

Square Meters Facility

Modern manufacturing complex with integrated design, production, testing, and quality assurance capabilities.

API 598 Testing

Every valve undergoes comprehensive pressure and seat leak testing per API 598 and EN 12266-1 standards.

Material Verification

Positive Material Identification on all incoming heats and finished components prevents material mix-ups.

Ready to Discuss Your Valve Requirements?

Our technical team is ready to support your project with expert consultation and competitive pricing. Contact us for detailed specifications and quotations.

Request Technical Consultation & Quote

Phone Support

+86-xxx-xxxx-xxxx

18-Month Warranty

Comprehensive coverage