Gate Valve vs Ball Valve: Main Differences Explained

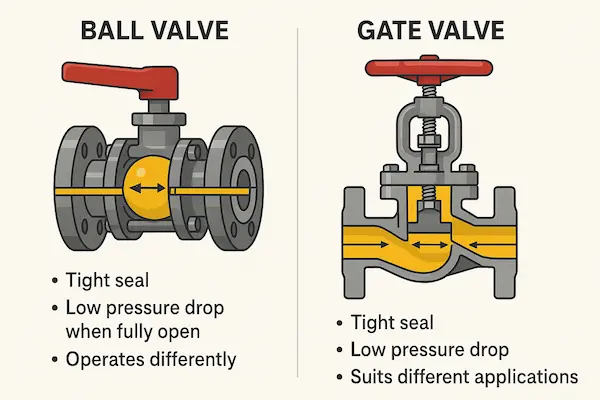

Visual comparison of ball valve and gate valve designs

Selecting the right isolation valve improves reliability, durability, energy efficiency, and automation while maintaining confidence in your operations. Two common valve types serve shut-off needs in plants, pipelines, and buildings: the ball valve and the gate valve, making it important to understand the differences in gate valve vs ball valve performance. Both designs offer a tight seal and low pressure drop when fully open, but they operate differently, require different maintenance, and suit different applications. Knowing the fluid dynamics within each valve design and how these interact with your pipe network is essential for making sound decisions.

Choosing between these valves affects safety, maintenance, cycle time, long-term durability, and system responsiveness—all factors that matter in high-performance environments.

How gate valve VS ball valve works

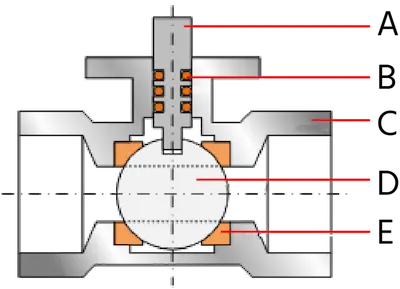

A ball valve uses a rotating sphere with a straight hole through its center. When the hole aligns with the pipeline, the fluid flows freely. A 90-degree rotation presents the solid side of the ball to the flow path, closing the valve. Sealing comes from soft seats made of PTFE or reinforced PTFE, ensuring a reliable seal. Metal-seated versions are available for high-temperature or abrasive service. The quick quarter-turn operation makes ball valves compact, fast-cycling, and ideal for automated control.

Ball valve internal structure and components

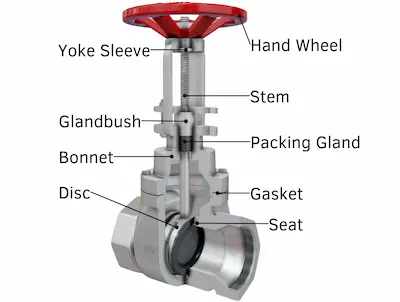

Gate valve internal structure and components

A gate valve uses a wedge or parallel gate that moves linearly to block fluid flow. A handwheel controls movement by raising or lowering the gate over several turns. In rising stem designs, the stem moves upward to show the position clearly; non-rising stem models keep the stem inside the bonnet, conserving vertical space. When fully open, the gate withdraws from the flow, creating a nearly straight bore along the pipe.

Both valve designs minimize resistance when open and provide a solid seal when closed, though their design differences lead to variations in performance and application.

Key differences gate valve VS ball valve at a glance

| Attribute | Ball Valve | Gate Valve |

|---|---|---|

| Motion | Quarter turn | Multi-turn |

| Cycle speed | Fast | Slow |

| Throttling quality | Poor with standard trim; very good with a V port or characterized ball | Poor; risk of seat and gate erosion |

| Pressure drop when open | Very low, especially for full port designs | Very low |

| Tight shutoff | Excellent with soft seats; metal-seated types vary | Metal-seated types may allow slight leakage; resilient seated waterworks gates are very tight |

| Cavitation risk when throttling | High near the closed position unless properly characterized | High near the seat if used for throttling |

| Automation | Simple and compact actuation | Requires larger multi-turn actuators |

| Size range availability | Common in medium sizes; larger sizes in pipe applications can be heavy and costly | Widely available up to very large diameters |

| Common services | Gas, liquids, clean or slightly dirty fluids, DBB, quick shut-off | Steam, extensive lines, high temperature, waterworks, pipelines |

| Seat materials | PTFE, RPTFE, UHMWPE, PEEK, metal | Metal, elastomer coatings (for waterworks gates) |

| Maintenance | Involves seats and stems, with attention to cavity relief | Includes packing, seat wear, and guides maintenance |

| Cost trend | Lower for small sizes; higher for large sizes and high-pressure classes | Competitive for large diameters and high-temperature service |

Flow performance and pressure drop

Both valve types are designed to provide low resistance when open. The flow coefficient, Cv, indicates the water volume that can pass through with a 1 psi drop. A higher Cv means less pressure loss—a crucial factor when evaluating fluid flow in a piping system.

Consider typical Cv ranges for 2-inch valves:

- Full port ball valve: 150 to 220

- Standard port ball valve: 90 to 150

- Gate valve: 140 to 200

These values depend on the manufacturer, port shape, and connection type, so always refer to the datasheet.

For example, with water at 100 gpm and a full port ball valve Cv of 180, the pressure drop ΔP is about .31 psi using the formula ΔP = (Q / Cv)² × SG. A standard port ball valve with a Cv of 120 sees roughly a .69 psi drop. The small difference in a single valve can add up in extensive piping networks. In a fully open condition, a gate valve also shows a minimal pressure drop. When the lowest pressure drop is needed, a full port ball valve is often the best option, but a fully open gate valve remains a reliable, low-loss choice.

Shutoff quality and leakage classes

Soft seated ball valves are known for their bubble-tight isolation and dependable shutoff performance. Many meet API 598 testing criteria with zero visible leakage when employing resilient seats. In fire-safe applications, ball valves are tested to API 607 or API 6FA, adding a secondary metal-to-metal seal when soft seats might fail under extreme conditions.

Gate valves typically rely on metal seats in industrial applications. These may allow a small degree of leakage under API 598 standards. In water distribution, resilient seated gate valves with elastomer-coated gates achieve tight shutoff even at moderate pressures. For high-temperature service, metal seats are the common choice.

When a zero-leak condition is required during normal operations, soft seated ball valves are preferred. For sustained high temperatures, a well-specified gate valve or metal-seated ball valve is the chosen option for safety and durability.

Throttling and control

Neither standard ball valves nor standard gate valves excel in precise flow control without risk. Both can be used in throttling applications, but caution is essential:

- Gate valves in partially open positions cause high edge velocities at the seat, risking erosion and leakage.

- Standard round-port ball valves show a nonlinear flow response where minor angle changes near the closed position produce large changes in Cv, creating unstable control behavior and risk of seat damage.

To improve control, consider a V port or characterized ball valve. These versions provide a more predictable flow curve and robust trim, making them better for flow control applications. In demanding conditions—such as high temperatures or differential pressures—a globe valve or angle valve with appropriate trim may perform better than either a standard ball or gate valve.

Media compatibility and wear

Media compatibility plays a key role in valve performance and longevity. Abrasion, solids, and general wear conditions affect the choice:

- Knife gate valves, a specialized variant, cut through slurries and fibrous materials while maintaining open flow paths.

- Soft seated ball valves work well with clean liquids and gases. In abrasive environments, metal-seated ball valves with proper coatings can be effective, though they may require higher torque and cost.

- Debris can collect in the cavity behind ball seats, possibly entrapping pressure. Vented ball or cavity relief designs help prevent this issue.

- For handling viscous fluids, both gate valve vs ball valve types perform adequately, though full port ball valves offer a smooth bore and easier cleaning.

Temperature and pressure limits

Seat material largely determines the temperature limits for ball valves. Typical thresholds are:

- PTFE and RPTFE handle up to around 400°F to 450°F

- PEEK supports up to about 500°F

- Metal seated designs can operate at temperatures beyond 800°F, depending on specifications

Gate valves with metal seats are well suited for high-temperature steam lines without needing major design changes to the trim. Pressure ratings follow ASME B16.34 and depend on the valve class, usually ranging from Class 150, 300, 600, or higher for heavy-duty conditions. When both high pressure and temperature are present, careful selection of body material, seat construction, packing, and test standards is vital. Low-temperature service also demands rigorous attention to material toughness.

Actuation and cycle speed

Ball valves, with their quarter-turn operation, pair well with compact electric or pneumatic actuators. Their quick travel times—often within a few seconds—make them suitable for rapid shut-off and safety-critical applications.

Conversely, gate valves require several turns to operate. Automating these valves means using gear operators or electric multi-turn actuators. Their slower closing speeds can help prevent sudden pressure surges in a piping system, providing more controlled pressure changes. Fast-closing ball valves may cause water hammer if not properly managed, so travel times should be controlled or supplemented with surge arrestors or relief systems.

Sizes and end connections

Both valve types come in various end connections, including threaded, socket weld, butt weld, and flanged designs.

- Ball valves are available in sizes from very small fractional units up to about 12 inches in full port configurations. For larger diameters in pipe applications, the valves can become heavy and expensive.

- Gate valves are common in large diameter systems and can be found in sizes 24 inches and larger, particularly in water and pipeline uses.

Face-to-face dimensions follow ASME B16.10, and ball valve actuator mounts typically conform to ISO 5211, making actuator selection easier. Both ball and gate valves for pipelines tend to meet API 6D standards, and pressure testing usually follows API 598 or ISO 5208.

Maintenance and reliability

Ball valves with soft seats offer low torque and low maintenance in clean service settings. Components like seats, body seals, and packing need periodic checks, and designs often incorporate cavity relief to release trapped pressure. Vented or automatic cavity relief designs help ensure a secure seal over the valve’s lifespan.

For gate valves, careful clearances and guides maintain wedge alignment. Over time, the wedge and seats wear, and the packing may leak at the stem. Rising stem designs offer easy visual checks and improved packing maintenance, while non-rising designs conserve space at the expense of visibility. Regular operation helps prevent stickiness, especially in systems prone to scale, polymers, or sediment buildup.

Cost and lifecycle

- Initial purchase: Small ball valves are generally more cost-effective than comparable gate valves and require simpler automation. In larger sizes and high-pressure classes, ball valves can become more expensive than gate valves.

- Actuation: Compact quarter-turn actuators for ball valves reduce costs, while multi-turn actuators for gate valves are larger and cost more.

- Operating costs: Both valve types provide low pressure loss when fully open, but frequent operation tends to favor ball valves due to fewer moving parts and lower torque, assuming the service conditions are within seat limits.

- Repairability: Designs exist for both valves that allow in-line repairs at high classes. Replacing soft seats is straightforward, whereas lapped metal seats on gate valves require specialized attention.

When assessing lifecycle costs, small to medium ball valves are commonly preferred for reliable on-off service, while gate valves are effective for larger sizes and conditions that drive up ball valve costs.

Safety and compliance notes

- Fire-safe performance: Specify fire-test certifications for hydrocarbon service or fire risk. Many ball valves carry API 607 or API 6FA approvals, while fire-safe gate valves use metal seats and proper packing.

- Double block and bleed: Trunnion-mounted ball valves often support double block and bleed (DBB) or double isolation. Some gate valves achieve similar results using body taps and specialized seal geometry.

- Fugitive emissions: Both designs offer low-emission packing systems with certified tests (e.g., ISO 15848). Always confirm the applicable standard for your application.

Selection checklist

- Required shut-off tightness at operating pressure

- Temperature range and seat material limits

- Media characteristics: whether clean, corrosive, abrasive, fibrous, or polymerizing

- Differential pressure during operation

- Need for throttling compared to simple isolation

- Flow control requirements for fine process adjustments

- Frequency of cycling and desired travel time

- Size and weight constraints in pipe installations

- Ease of automation and available utilities

- End connection and face-to-face dimensions

- Compliance with fire safety and emission standards

- Maintenance approach, including in-line repair capabilities and spare parts management

When ball valves shine

- Best for rapid on-off operations and frequent cycling in dynamic piping systems

- Provides a tight shutoff for gas and light hydrocarbon applications

- Compact and efficient when used with pneumatic or electric quarter-turn actuators

- Offers full bore designs that support pigging or high Cv values for effective fluid dynamics

- Can support double block and bleed functions using trunnion designs

- Works well in clean fluid processes or moderate solids conditions when paired with appropriate seats and coatings

When gate valves make sense

- Suitable for high-temperature steam service where metal seats offer long-term durability

- Preferred for very large line sizes where ball valves become unwieldy and costly

- Appropriate for systems with low-frequency operation on extensive pipelines and water distribution networks

- Beneficial where gradual closing helps manage pressure changes and minimize surges

- Ideal when maintenance teams are experienced with packing replacement and wedge servicing

Common myths, cleared up

• Myth: Ball valves always provide lower pressure drop.

Reality: Full port ball valves tend to yield lower pressure drops, but a fully open gate valve can be just as efficient depending on port geometry.

• Myth: Gate valves are inherently leaky.

Reality: Modern resilient seated gate valves can seal very tightly, though metal-seated designs may allow a small amount of leakage.

• Myth: Ball valves cannot throttle effectively.

Reality: Modified designs, such as V port or characterized ball valves, offer solid modulation when properly specified.

• Myth: Gate valves are outdated.

Reality: Gate valves remain essential for high-temperature, large-diameter applications due to their robust construction and cost-effectiveness.

Real-world sizing tips

For processes with clean gas or solvents that require rapid shutoff, start with a full port ball valve sized to the pipeline, ensuring the actuator can handle maximum differential pressure. In a steam application at 600°F using Class 600 piping, a metal-seated gate valve typically meets the necessary temperature and pressure demands with regular maintenance. When intermittent throttling is needed, a V port ball valve with a tailored control characteristic may serve as both an on-off and modulating control device. Validate the control valve authority and system curve to achieve a proper flow range and performance.

Installation and operation pointers

Make sure that heavy actuators are properly supported to prevent bending loads on the valve body. Use suitable gaskets and evenly torque flange joints to maintain seat integrity. Regularly exercise valves that sit idle to avoid sticking. In gas service, incorporate antistatic measures and proper grounding for ball valves. For systems experiencing thermal cycles, check and adjust packing and bolt torques periodically. When surge is a potential issue, set actuator travel times carefully and consider using snubbers or additional flow control devices to prevent abrupt closures.

Standards and references worth knowing

- ASME B16.34 governs pressure-temperature ratings and basic valve requirements.

- ASME B16.10 covers face-to-face dimensions.

- API 598 or ISO 5208 standardize pressure testing protocols.

- API 6D applies to pipeline valves.

- API 607 and API 6FA cover fire testing criteria.

- ISO 5211 defines actuator mounting procedures.

- FCI 70-2 sets control valve seat leakage classes, which is relevant when choosing characterized ball valves for control applications.

Quick FAQ

Q: Can I use a ball valve for steam?

A: Yes, if you select a high-temperature metal-seated ball valve or one with specialized seat materials that match your operating conditions.

Q: Why might a ball valve become hard to turn?

A: Problems like seat swelling, debris in the cavity, or high differential pressure can increase torque. Regular cleaning, proper cavity relief, and correct actuator sizing help maintain smooth motion.

Q: Do gate valves seal in both flow directions?

A: Most industrial gate valves are designed for bidirectional sealing, although knife gate designs or specialized seats may prefer a particular flow direction. Check the datasheet for exact details.

Q: Is a full port ball valve always preferable to a standard port valve?

A: Full port ball valves typically provide lower pressure loss and better pigging capability, but they can be heavier and more expensive. If your system can handle a slightly higher pressure drop, a standard port ball valve may be acceptable.

Q: Can a gate valve be used for throttling when necessary?

A: While possible, throttling with a gate valve is not recommended. Partial operation increases the risk of seat damage and cavitation, so use throttling only when absolutely necessary.

Choosing between gate valve vs ball valve becomes straightforward when you match specific requirements such as shutoff tightness, temperature tolerance, size, cycling frequency, and control needs. This careful mapping of factors ensures optimal performance across a wide range of applications.

Contact Us

Need expert advice on valve selection for your specific application? Contact our technical team for personalized recommendations.