Stop Valves: Understanding Essential Flow Control

A comprehensive guide to the quiet heroes of flow control – stop valves that provide reliable isolation in every piping system

A quiet hero sits between your water main and the sink, between a process pump and a reactor, between a steam header and a coil.

Turn a handle, and the line is open or closed by the mechanism. That simple action, repeated millions of times a day across buildings and plants, depends on one device: the angle stop valve.

What a Stop Valve Actually Does

\n

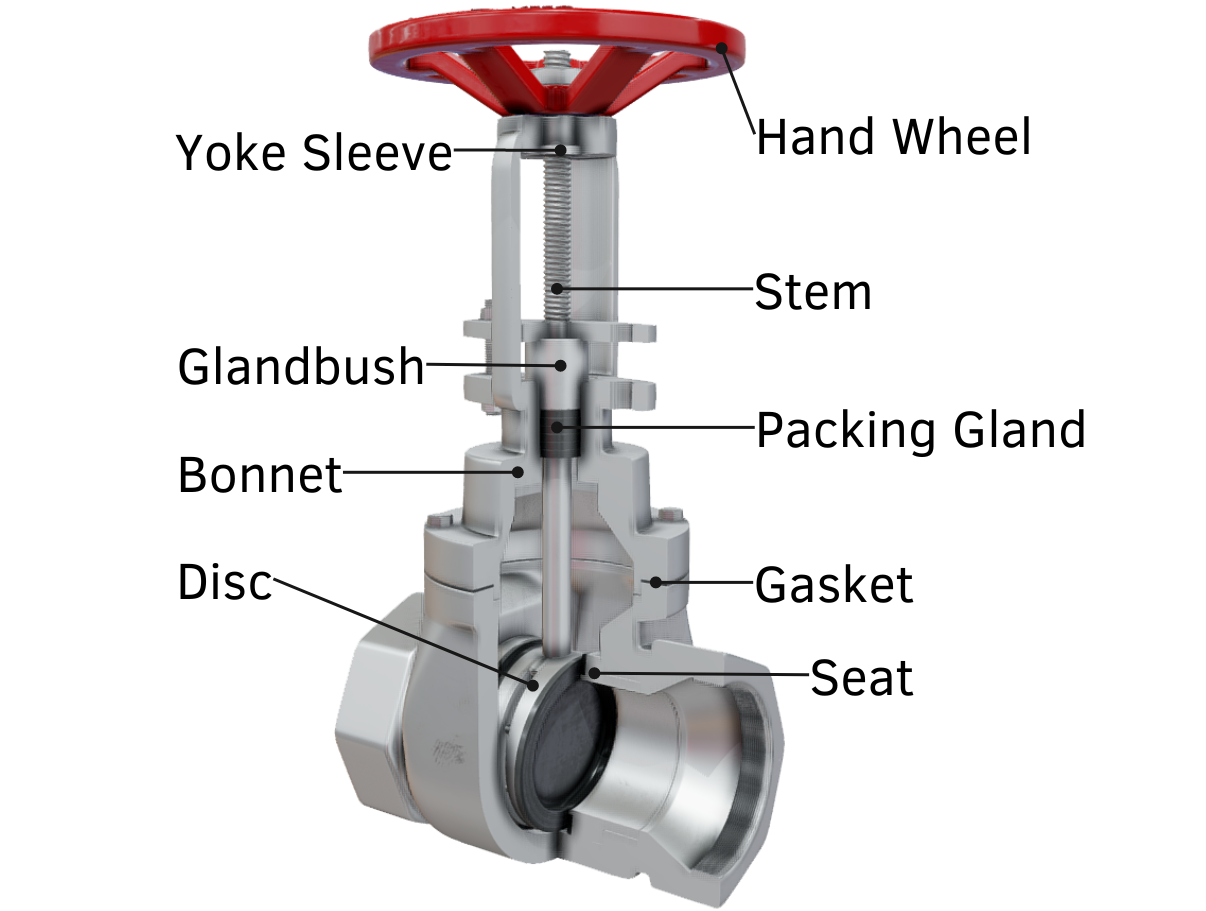

Figure 1: Gate valve cross-section showing internal components and flow control mechanism

A stop valve isolates. It provides a clear yes or no to flow so technicians can service downstream equipment, limit damage during a leak, or segment a system for testing.

Unlike a control valve that modulates to hold a setpoint, a stop valve is all about reliable shutoff with minimal fuss. It’s indispensable in both traditional and non-traditional environments, offering precise controls for isolation.

The best ones feel boring. They sit for years, close fully when called on, then reopen without drama. That predictability is crucial when considering both performance and price.

Where You Find Them

\n

Figure 2: Angle stop valve installation under sink showing typical residential application

Under every sink and toilet as fixture shutoffs

On branch lines feeding water heaters and HVAC coils

On steam drops, condensate returns, and blowdown lines

On fuel gas skids and burner trains

In chemical plants at equipment nozzles and maintenance boundaries

On compressed air headers and instrument air drops

In fire protection, medical gas, and clean utility systems

The setting changes. The purpose stays the same.

Anatomy in Brief

Most stop valves, including the angle stop valve, share a small set of parts:

- Body and bonnet that contain pressure

- Seats that seal the flow path

- A closure member: gate, ball, plug, disc, or needle

- A stem that translates hand motion to closure motion

- Packing that seals around the stem

- End connections that tie into the piping

Two design families dominate: linear motion and quarter-turn mechanisms. That split influences everything from pressure drop to maintaining a straight operation.

Linear Motion Options

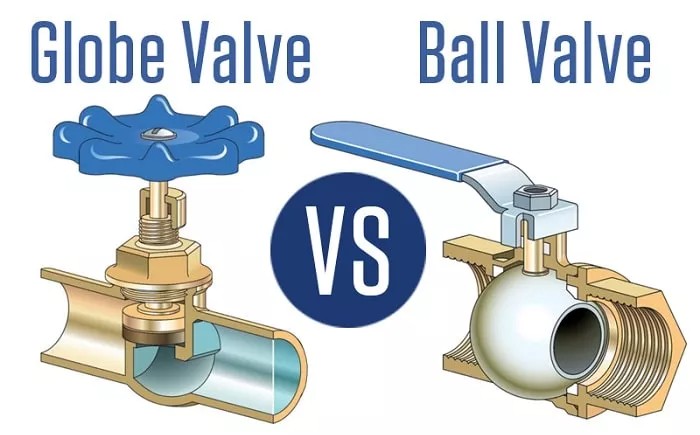

Figure 3: Comparison of globe valve and ball valve designs showing internal mechanisms

Gate Valves

A gate valve lifts a plate straight out of the flow path, highlighting its main function in controlling water flow.

When open, the port is nearly the same size as the pipe, which means very low pressure drop. When closed, the gate wedges into the seats to isolate.

Strengths:

- • Minimal pressure loss in the open position

- • Good for on-off in large diameters

- • Simple internal geometry

Limitations:

- • Poor throttling behavior

- • More turns to operate, so slower to close

- • Seats can trap solids

Use gates where you need line-size passage and infrequent operation, for example, on main headers.

Globe Valves

A globe valve uses a disc moving straight toward a seat in a changing flow path. That shape handles throttling far better than a gate, though it has higher pressure drop when open.

Strengths:

- • Better control of flow during partial opening

- • Predictable Cv change per turn

- • Robust against cavitation in many trims

Limitations:

- • Higher energy loss when open

- • Heavier and taller than a comparable ball valve

Globe patterns include straight, angle, and Y types. Y-pattern globes reduce pressure loss and suit high-pressure service.

Needle Valves

A slim, tapered stem and seat yield fine control at small flows, often requiring precise angle adjustments.

Common on instrumentation and sampling lines, not on mains.

Quarter-Turn Options

Figure 4: Ball valve installation showing proper positioning and flow direction

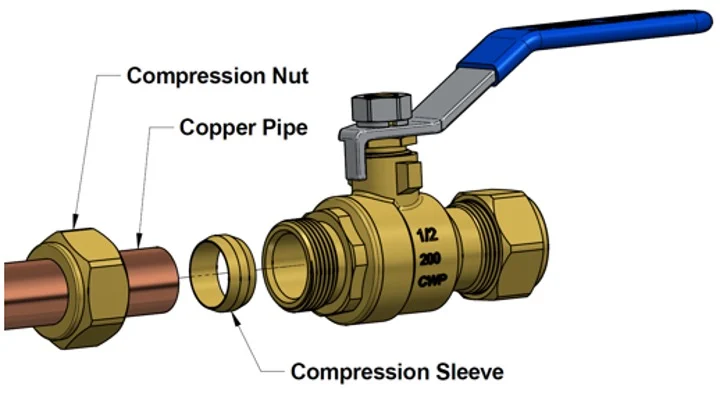

Ball Valves

A bored sphere rotates a quarter turn to open or close. Soft seats deliver tight shutoff with low torque.

Polished chrome two-piece, three-piece, and trunnion-mounted designs cover everything from residential to high-pressure hydrocarbon service.

Strengths:

- • Quick quarter-turn operation

- • Bubble-tight shutoff with soft seats

- • Low pressure drop

Limitations:

- • Not ideal for throttling unless designed for it

- • Seat damage if cycled against solids or at high delta P

Choose full-port for pigging or minimal pressure loss. Reduced-port saves cost and weight, often utilizing outer diameter measurements for sizing.

Plug Valves

A tapered or cylindrical plug with a through passage rotates to stop flow.

Lubricated plugs handle dirty service. Sleeved plugs offer low torque and chemical resistance.

Strengths:

- • Simple, rugged design

- • Tolerant of contaminants in many variants

Limitations:

- • Torque can rise with wear or temperature

- • Throttling depends on geometry and can be tricky

Stop-Check Valves

These combine a stop function with a check feature.

A manual operator can force the disc onto the seat or hold it open, while normal operation allows check action. Common on boiler feedwater and steam service.

Stop and Waste Valves

Used in irrigation and cold climates.

Closing the valve also opens a small drain port to empty downstream piping and prevent freeze damage.

How to Choose the Right Stop Valve

Start with the service conditions and work outward, taking into consideration the operational requirements.

Pressure and temperature:

Match the design rating and end connection standard to your system. ASME B16.34 covers a wide range of materials and classes. Check body marking against the class you need.

Media:

Water, steam, hydrocarbons, acids, slurries, oxygen, and clean gases each drive different seat and packing choices. PTFE or elastomer seats give tight shutoff for clean service. Metal seats handle heat, abrasion, and fire scenarios.

Materials:

Brass and bronze for potable water and low-pressure service. Carbon steel for steam and hydrocarbons. Stainless steel for corrosion resistance. PVC and CPVC for many chemicals and lower temperature. Duplex or alloy steels for chlorides and severe duty. Polished chrome provides a sleek finish and enhanced durability in decorative fixtures.

End connections:

Threaded NPT and BSPP for small sizes. Flanged to ASME B16.5 for easier maintenance and alignment. Socket weld or butt weld for high pressure. Press-fit and push-fit for residential and light commercial.

A candid chat with your process and safety teams pays dividends. A wrong choice here can bring more downtime than any other piping item.

Flow capacity and sizing

The common sizing metric is Cv, the US valve flow coefficient. Cv is the gallons per minute of water at 60°F that results in a 1 psi pressure drop across the valve at a given opening. For SI work, Kv is common.

A quick example makes this concrete:

- Flow: 50 gpm water

- Allowable pressure drop across the stop valve: 3 psi

- Required Cv = Q × sqrt(SG) divided by sqrt(delta P) = 50 × 1 divided by sqrt(3) = about 28.9

A full-port 1.5 inch ball valve might deliver that Cv, while a globe of the same size might deliver far less when throttled and more when fully open. Vendors publish Cv by size and opening position. Use those tables, then apply a margin based on fouling and future expansion.

Avoid sizing a gate valve to throttle in the middle. The sharp edges of a partially open gate can cavitate and vibrate, chewing up the seats. If you need partial flow control, pick a globe or a V-notch ball designed for throttling.

Pressure Drop, Cavitation, and Noise

Stop valves, including straight stop valves and angle stop valves, can be a surprising source of energy loss, vibration, and operational disruption if the controls are misapplied.

High delta P at partial opening speeds erosion

Flashing and cavitation pit downstream surfaces

Rapid closure on fast flows triggers water hammer

Gas flows at choked conditions can howl

Mitigation tools include anti-cavitation trims for globes, slower actuation, snubbers, and flow-limiting orifices upstream of the valve. In liquids, aim for reasonable valve authority without forcing the stop valve to do the control valve’s job.

Installation practices that pay off

Figure 5: Professional installation of shut-off valve showing proper technique and positioning

Installation Guidelines

Orientation:

Many valves are happy in horizontal or vertical lines, and the angle of installation can affect performance. Check the arrow for flow direction on globes and stop-checks. Some designs rely on pressure to help seal properly.

Access:

Leave room to swing a lever or remove a bonnet. Skipping clearance will cost you during your first packing change.

Support:

Large valves are heavy. Pipe strain can distort bodies and cause leakage or premature wear. Use hangers or supports near flanged and heavy valves.

Best Practices

Cleanliness:

Debris left in a new line can scar seats during the first closure. Flush or blow out the line before installation, then again before the first operation.

Gaskets and torques:

Match flange facings and use the correct gasket material. Torque bolts in a cross pattern to the proper value.

Note on under-sink shutoffs: Angle stop valves often see mineral deposits and stiff action. After installation, cycle them a few times and leave them either fully open or in the designed set position to avoid weeping at the stem.

Maintenance Routines

A light, regular touch keeps stop valves dependable.

Inspect for packing leaks

A small drip or white residue at the stem calls for a quarter turn on the gland follower. Do not overtighten.

Exercise seldom-used valves

One or two full cycles every few months prevents sticking and helps distribute lubricant.

Replace packing when needed

Use compatible materials and follow the layer-and-split installation method where applicable.

Watch for warning signs

Handle position drift or hard stops mid-travel are signs of seat or stem damage.

Pro tip: Three-piece ball valves make online seat and seal changes much easier. In welded systems, consider valves with serviceable internals to reduce downtime.

Operation and Safety

Stop valves can be fast. That’s usually good, until it isn’t.

In steam and condensate systems, warm up lines with crack-open positions before full opening. Temperature gradients and slugging are unkind to piping and people.

Automation and Actuation

Not every stop valve needs a hand on it. Automated actuators offer speed, remote operation, and safety interlocks.

Pneumatic:

Fast, reliable, and simple, using tubing layouts. Add solenoids, positioners, and lockup valves for fail-safe behavior.

Electric:

Convenient where air is not available. Check duty cycle and torque at temperature extremes.

Hydraulic:

High torque in tight spaces. Less common in building systems, more in heavy industry.

Define fail position clearly. Fail-closed means spring or accumulator force drives the valve shut on power loss. Fail-open maintains safety flow to a relief or cooling circuit. For critical isolation, two block valves with a bleed between them provide verification and pressure relief.

Codes and Standards Snapshot

Keeping a short list handy saves time:

API 598 and ISO 5208: Valve inspection and pressure testing

ASME B16.34: Valve design and pressure temperature ratings

ASME B16.5: Pipe flanges and flanged fittings

MSS SP-61: Pressure testing of steel valves

API 607 and ISO 10497: Fire testing of quarter-turn valves

ISO 15848 and API 641: Fugitive emissions

UPC and IPC: Local plumbing codes for fixture shutoffs and accessibility

NFPA 99: Medical gas zone valves and labeling

CSA, NSF/ANSI 61, and 372: Potable water safety and lead content

Always align product markings and paperwork with the inspection plan. Audits love organized traceability.

A quick comparison

| Valve type | Best use | Throttling | Pressure drop when open | Shutoff tightness | Typical materials | Notes |

|---|---|---|---|---|---|---|

| Gate | Main isolation on clean liquids | Poor | Very low | Good with proper seating | CS, SS, bronze | Avoid mid-stroke throttling |

| Globe | On-off with controlled opening or moderate throttling | Good | Moderate to high | Very good with proper trim | CS, SS, bronze | Y-pattern for high pressure |

| Ball | Fast shutoff on clean fluids and gases | Fair with V-port | Low | Excellent with soft seats | Brass, CS, SS, PVC | Quarter-turn, easy automation |

| Plug | Dirty service, hydrocarbons, vapor lines | Fair | Low to moderate | Good | CS, SS, alloy | Lubricated or sleeved designs |

| Needle | Fine flow control in small lines | Excellent at small flows | High for size | Very good | SS, brass | Instrumentation and sampling |

| Stop-check | Steam and feedwater with backflow control | Poor | Moderate | Good | CS, alloy | Manual override of check function |

| Stop and waste | Irrigation and seasonal lines | Poor | Moderate | Good | Brass | Drain port protects from freeze |

CS = carbon steel, SS = stainless steel.

Common problems and how to respond

Handle turns but flow does not stop:

The stem may be sheared or disconnected from the closure member. Plan a shutdown and replace internals or the valve.

Valve is stuck:

Mineral scale or corrosion has seized the stem. Apply penetrant, gently work the handle back and forth in a straight motion, and avoid over-torque. Heat and cool cycles can help, but be mindful of packing and nearby plastics.

Drip at the stem:

Snug the packing gland a bit. If it persists, repack with the correct material.

Buzzing and chatter during partial opening:

Cavitation or unstable flow. Switch to a trim suited for throttling or move the duty to a control valve or controls upstream.

Weeping at flanges:

Re-torque bolts after thermal cycles. Replace gaskets if creep has relaxed the joint.

Keep spares for critical services, including seat kits, stems, and packing sets. Small parts prevent long outages.

Tips for Fixture and Building Shutoffs

Residential and light commercial work brings its own patterns.

A five-minute walk-through of an existing building often reveals missing, hidden, or frozen shutoffs. Fixing that layout improves response during an emergency more than any single piece of equipment.

Safety Notes for Higher Hazard Fluids

Hydrocarbons, acids, oxygen, and toxic gases raise the stakes.

Work with the process hazard analysis and relief system team so isolation does not defeat overpressure protection.

A Short Buying Checklist

Service data: fluid, temperature, pressure, line size, solids, viscosity

Function: on-off only, or occasional throttling

Materials: body, trim, seats, packing compatible with media

Connection: NPT, BSPP, flanged, socket weld, butt weld, press

Standards: design, test, emissions, fire-safe as required

Certification: UL, FM, NSF, CRN, CE, PED, SIL where relevant

Operation: manual, pneumatic, electric, fail position

Environment: ambient temperature, corrosion, space, accessibility

Maintenance: repair kits, interchangeability, spare parts strategy

Send this list with your RFQ. Vendors respond faster and more accurately when the service is clear, often providing competitive price options.

Short FAQ

Q: Can I throttle with a ball valve? A: Yes, but only with a design and trim meant for it, like a V-port ball. Standard round-port balls can wear seats and chatter at partial openings.

Q: Why does my gate valve not fully stop flow? A: Debris may be trapped on the seat, the wedge may be worn, or the stem threads may be stripped. Cycling and flushing might help, but plan for repair or replacement.

Q: What does bubble-tight mean? A: In low-pressure gas testing, no visible bubbles appear in a set time using a specified method. ISO 5208 Rate A is a common reference for that level of tightness.

Q: How often should I exercise shutoff valves? A: Cycle critical ones quarterly. Less critical ones at least twice a year. Document the results and flag any that feel gritty or hard to turn.

Q: Which is better, brass, stainless, or other materials? A: Neither in all cases. Brass is common and cost-effective for potable water. Stainless shines with corrosion resistance, higher temperatures, and clean service. Match the material to the media and code requirements.

Contact Us

Need expert consultation on stop valve selection or installation? Our technical team is here to help with your specific application requirements.

Contact Form

Expert guidance for reliable flow isolation systems

When isolation mechanisms work every time, maintenance schedules hold, spills stay small, and projects finish on time.

That quiet hero deserves careful selection and care.