Ball Valve Basics: Flow Control 101

Whether you manage a factory line, run a building’s mechanical systems, or just love the clarity of a well-designed machine, few pieces of hardware feel as satisfying as a ball valve clicking from open to closed. Quarter-turn, compact, and reliable, these ball valve designs show up everywhere from breweries to refineries to rooftop chillers because they do one thing very well: control flow—with precise flow control—with minimal fuss. In many plumbing systems, these ball valves and related fittings work together to create reliable control systems for both liquids and gases. For instance, a well-chosen gas valve based on ball valve principles can ensure safe and efficient operation in demanding applications.

Table of Contents

What is a Ball Valve?

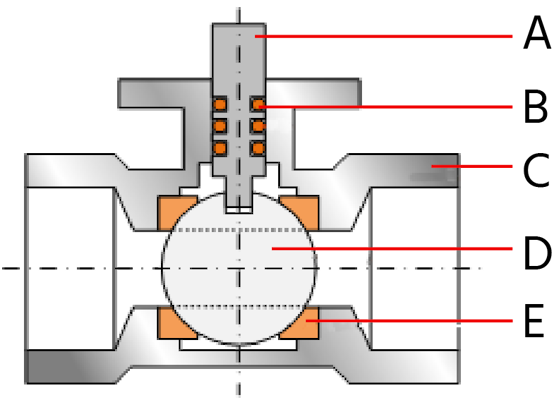

Ball valve components and structure

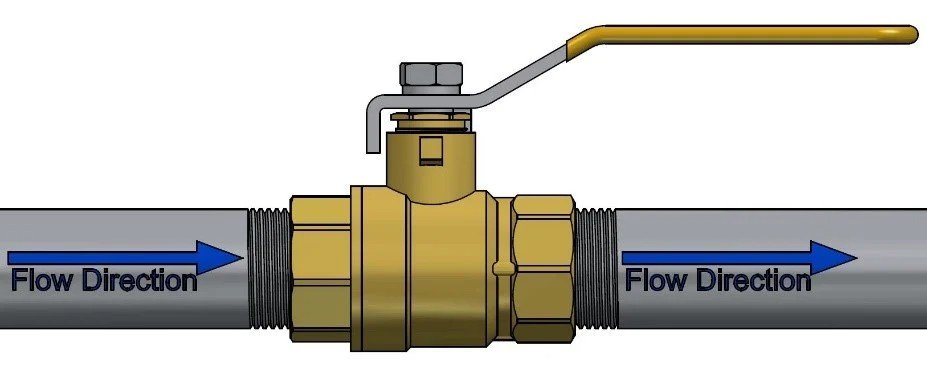

A ball valve is a quarter-turn valve that uses a perforated sphere to start or shut off fluid flow. Rotate the handle 90 degrees and the hole either lines up with the pipeline to allow flow or turns perpendicular to block it. That’s the essence of a ball valve. Whether using a valve with manual actuation or automated options, its simplicity makes it popular in many applications.

Key Traits:

- Fast action with a simple 90-degree turn that provides an effective shut off

- Tight shutoff with soft seats, often bubble-tight

- Compact size compared with gate and globe valves, which makes them ideal for various plumbing applications

- Low pressure drop in full port designs

People choose ball valves when they need quick shut off, low maintenance, and consistent sealing. Although they originally date back to simple on-off control, modern ball valve technology—even in electric ball valves and pneumatic ball valves—has advanced significantly to serve not only industrial applications but also flow control challenges in sensitive process loops. They are not always the first pick for precise throttling, yet the right design (including specialized high pressure ball valves) can handle modulating service very well.

How Does a Ball Valve Work?

Inside the body, a polished ball with a hole sits between two seats. Turning the stem rotates the ball. When the hole aligns with the pipeline, fluid flows through. Turned perpendicular, it blocks flow. The stem is sealed by packing and usually incorporates an anti-blowout feature that prevents the stem from being ejected under pressure.

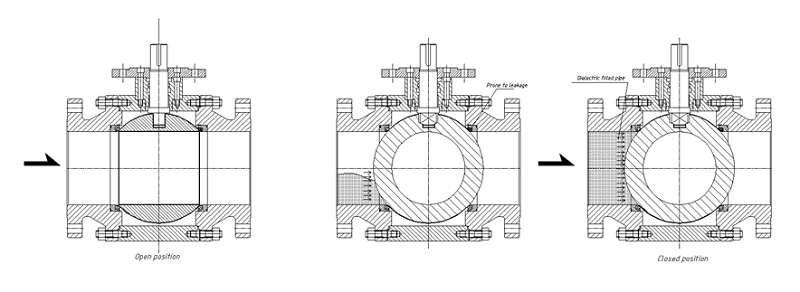

Comparison between floating and trunnion mounted ball valves

Two Internal Support Styles:

- Floating ball: The ball is held by the seats and shifts slightly downstream under pressure to improve sealing. Common in smaller sizes and lower pressures.

- Trunnion mounted ball: The ball is anchored by trunnions top and bottom. Seats are spring-loaded against the ball. Used in larger sizes and higher pressures to reduce operating torque.

Seat materials set the tone for sealing and temperature range. PTFE seats give low friction and a clean shut off. Filled PTFE, PEEK, and metal seats expand the envelope for temperature, abrasion, and dirty service. In fire-safe designs, soft seats burn away at high temperature and a metal-to-metal seal provides secondary shut off to meet standards.

Types of Ball Valves (2-Way, 3-Way, V-Port)

Ball valves come in several flow patterns and port geometries. Each solves a different control problem.

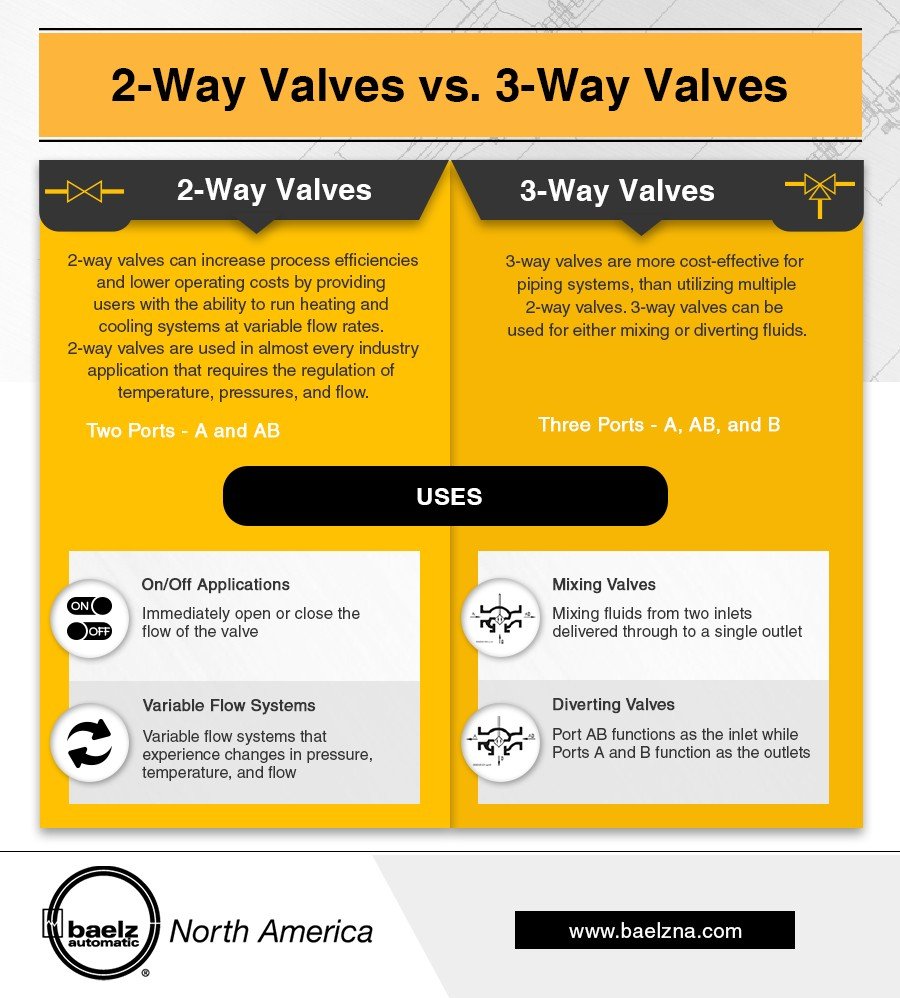

2-Way vs 3-Way valve flow patterns

2-Way Ball Valve

Featuring a straight-through path for on-off service, these valves provide a reliable and quick shut off. Choose full port for minimal pressure drop or reduced port for compact size and cost savings.

3-Way Ball Valve

In configurations such as L-port or T-port, these valves route or mix flow. An L-port three way ball valve switches one inlet to two outlets or vice versa.

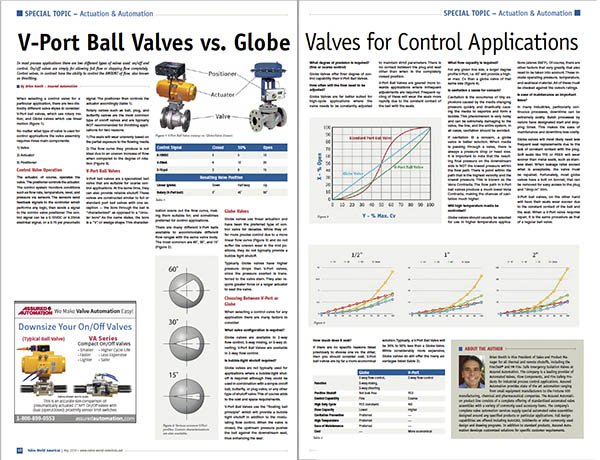

V-Port

The ball has a V-shaped notch that enables modulating control. As the valve opens, the flow area increases in a predictable way, improving controllability for flow control applications.

V-Port ball valve for flow control applications

Other Important Distinctions:

- One-piece, two-piece, and three-piece bodies. Three-piece designs simplify seat and seal replacement in-line.

- End connections: threaded connection, socket weld, butt weld, flanged, tri-clamp for sanitary service, or even press fitting for quick assembly in light industrial applications.

- Actuation options: manual lever for manual actuation, gear operator for large diameters, pneumatic or electric actuators.

Ball Valve Materials and Applications

Stainless Steel Ball Valve

Threaded Connection

Flanged Ball Valve

3-Way T-Port/L-Port

Choosing the right metallurgy and soft goods is as important as picking the flow pattern. Corrosion, temperature, and cleanability all matter. Here is a quick guide.

| Component | Common Materials | Pros | Limits | Typical Uses |

|---|---|---|---|---|

| Body | Brass, bronze | Affordable, easy to machine | Not ideal for many chemicals | Residential water, low-pressure air |

| Body | 304/316 stainless steel | Corrosion resistant, cleanable | Cost higher than carbon steel | Food, pharma, chemicals, steam service |

| Body | Carbon steel | Strong, cost-effective | Requires coating, corrosion risk | Oil and gas, general industrial |

| Body | PVC | Lightweight, corrosion resistant | Not suitable for high temperature | Chemical processing, water treatment |

| Ball | 316 stainless, chrome-plated | Smooth sealing surface | Coatings wear in abrasive slurries | Broad industrial service |

| Seats | PTFE | Low friction, clean shut off | Temperature limited, can cold-flow | Water, air, clean chemicals |

| Seats | Reinforced PTFE, PEEK | Better temperature and pressure | Higher torque, cost | Steam, solvents, high-pressure gases |

| Seats | Metal (Stellite) | High temperature, abrasive service | Not bubble-tight at low pressure | Refining, power, severe service |

| Seals | PTFE, graphite, elastomers | Tailored for media | Compatibility varies | Select based on media and temperature |

Industry-Specific Notes:

- Sanitary: 316L bodies, cavity-filler seats, tri-clamp ends, FDA and 3-A conformity.

- Sour service: Materials that comply with ISO 15156 or NACE MR0175 for H2S exposure.

- Cryogenic: Extended bonnets move the packing away from the cold zone.

- Fire-safe: API 607 or similar-tested valves for hydrocarbon service.

Advantages and Disadvantages

Ball valves earned their popularity by solving real field problems. They also come with tradeoffs. Weigh both sides before specifying.

Advantages:

- Quarter-turn actuation for fast isolation

- Bubble-tight shut off with soft seats

- Low pressure drop in full port versions

- Compact footprint and simple mechanism

- Straightforward automation with ISO mounting

- Broad material choices for various media

- Reliable operation across thousands of cycles

Disadvantages:

- Standard seats may not suit continuous throttling

- Cavity can trap media causing pressure buildup

- Higher torque with reinforced or metal seats

- Not ideal for slurries without hard seats

- Temperature derating reduces pressure capacity

How to Choose the Right Ball Valve

Cutaway view showing internal components

Start with the process conditions. A quick checklist helps narrow choices quickly.

Initial Checklist:

- Media: Clean, dirty, abrasive, sticky, or corrosive

- Temperature and pressure across the operating envelope

- Required function: on-off, diverting, mixing, or modulating

- Size and end connections to match piping code

- Actuation: manual, pneumatic, electric, fail-open or fail-closed

- Standards and approvals that apply to your site

Detailed Considerations:

- Port type: Full port when pressure drop must be minimal or when pigging. Reduced port where compact size is beneficial.

- Body style: Three-piece bodies save time during seat changes and cleanout.

- Seats and seals: Pick materials based on chemical compatibility and temperature.

- Safety: Look for blowout-proof stem design, antistatic devices in hydrocarbon service.

- Maintenance approach: In-line serviceable valves reduce labor costs.

Sizing and Pressure Ratings

Size for flow, not just pipe diameter. An oversized ball valve can lead to poor control in modulating service.

- Estimate required flow and allowable pressure drop

- Use Cv or Kv data from the manufacturer

- For V-port valves, choose a trim angle that matches your control curve

- Check velocity limits to protect seats from erosion

- Verify noise and cavitation risk for high differential pressure

Installation and Maintenance Tips

Proper installation technique

Threaded valve installation

Good installation protects your investment. Ball valves are robust, and they keep that reputation when mounted and maintained with care.

Before Installation:

- Inspect bore and seats for debris

- Confirm materials match specification

- Cycle valve to verify smooth operation

- Check end connections and gaskets

Mounting:

- Support piping to avoid valve stress

- Use compatible sealants for threads

- Follow torque specs for flanges

- Check orientation for 3-way valves

Maintenance Best Practices:

- Cycle rarely used isolation valves on a schedule to prevent sticking

- Monitor packing for small leaks. Tighten incrementally

- Replace soft seats and seals at planned intervals in critical service

- Keep spare kits on hand: seats, stem packing, body seals

- In dirty service, consider line strainers or purge connections

Troubleshooting Quick Hits:

- Stem leak at packing: tighten packing gland slightly or replace rings

- Hard turning: check for over-tight packing, debris in seat, or actuator misalignment

- Leakage past seat: inspect for scratches on ball, damaged seats, or trapped debris

- Actuator fails to move: verify power or air, check solenoids and positioners

FAQs About Ball Valves

What makes a ball valve different from a gate or globe valve?

A ball valve is quarter-turn with a spherical closure and often gives tight shut off and low pressure drop. Gate valves isolate well but operate slowly with multiple turns. Globe valves excel at throttling with a more linear control response but have higher pressure drop.

Can a ball valve be used for throttling?

Yes—with the right design. V-port balls and high-performance seats handle modulating service well. Standard full-bore balls close off quickly and can be jumpy in control loops, especially at small openings.

What is full port versus reduced port?

Full port keeps the bore near the pipe inner diameter, minimizing pressure drop and allowing pigging. Reduced port has a smaller bore, saving cost and size, but increases pressure drop.

What does fire-safe mean for a ball valve?

In a fire-safe design, soft seats may burn or deform, yet the valve still achieves a metal-to-metal seal that limits external leakage. Standards like API 607 define test methods.

How do I select seat material?

Match the seat to media, temperature, and pressure. PTFE handles many clean services. Reinforced PTFE and PEEK increase pressure and temperature capability. Metal seats suit high temperature and abrasive conditions.

Do ball valves trap pressure in the body cavity?

They can. The space between seats can trap liquid. Temperature changes may expand trapped fluid and raise pressure. Options include cavity relief holes or vented seats that relieve pressure to the upstream side.

Can I automate an existing manual ball valve?

Yes, if the valve includes an ISO 5211 mounting pad. A bracket and coupling connect the actuator to the stem. Verify torque, air or power availability, fail position, and control requirements.

Do ball valves handle steam?

Yes, with suitable materials. Use stainless or carbon steel bodies with high-temperature seats like reinforced PTFE, PEEK, or metal. Verify pressure-temperature ratings at steam conditions.

Ball valves in industrial field applications

Conclusion

This thorough discussion on ball valve technology—including the various types such as electric ball valves, pneumatic ball valves, and the specialized high pressure ball valves—underscores how these devices have become indispensable in modern flow control. When selecting a ball valve, always consider the associated fittings, the overall plumbing system, and the specific needs of your application—even if that means choosing a gas valve variant built on the same principles—to ensure optimal performance and longevity.

Need Help Choosing the Right Ball Valve?

Our experts are ready to help you find the perfect valve solution for your application.

Related Articles

Gate Valve vs Ball Valve

Learn the key differences between gate valves and ball valves to make the right choice.

Read MoreHigh Pressure Ball Valves

Discover specialized ball valves designed for extreme pressure applications.

Read MoreFire-Safe Ball Valves

Understanding fire-safe certification and applications for ball valves.

Read More