Flanged Ball Valve

Industrial piping systems demand secure, leak-free connections to prevent costly downtime and environmental risks. High-pressure and corrosive media present significant challenges to standard valve integrity and operational safety. Flanged ball valves provide a robust and reliable solution with bolted end connections for superior performance. These valves deliver positive, quarter-turn shutoff for critical flow control in demanding applications. Every valve is engineered to meet stringent industry standards, including API 6D and ASME B16.34, ensuring compliance. We manufacture variants from durable materials like stainless steel (SS) and bronze in 2-piece and floating ball designs. They are essential in oil and gas, chemical processing, power generation, and water treatment plants. Our engineering team can help you select the optimal valve for your system. Request a Quote →

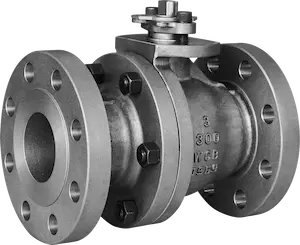

API 6D Floating Ball Valve

Industry-standard certified valves meeting API 6D specifications for critical applications.

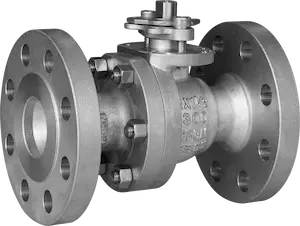

Stainless Steel Flanged Ball Valve

Corrosion-resistant SS 304/316 construction for demanding chemical and marine environments.

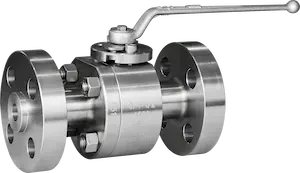

Flanged Floating Ball Valve

Versatile floating ball design with flanged connections for secure pipeline integration.

Key Features and Applications of Flanged Ball Valve

Flanged ball valves are quarter-turn valves featuring integral flanges for direct, secure bolting into a pipeline. This design adheres to API 608 specifications for industrial valve construction, ensuring reliability. This flanged connection provides a high-integrity, zero-leakage seal ideal for mission-critical and high-pressure systems.

The valve body encloses a perforated, pivoting ball that rotates to control flow. The flange ends eliminate the need for threaded or welded connections, significantly reducing potential leak paths. This robust construction simplifies both installation and maintenance, allowing for easy removal and servicing without cutting the pipe. This feature is particularly valuable for applications requiring periodic inspection and component replacement. The ANSI Flange Ball valve design ensures interchangeability and dimensional consistency across manufacturers.

- Ensures secure, bolted connections compliant with ANSI standards.

- Provides tight shutoff with a quarter-turn mechanism for rapid operation.

- Reduces potential leak paths compared to threaded valve alternatives.

- Simplifies in-line maintenance and component replacement.

Unlike threaded valves, flanged models are better suited for larger pipe diameters such as 2″, 3″, 4″, and 6″, and higher pressure classes including 150Lb and 300Lb. While functionally similar to a Trunnion Ball valve, the floating ball valve design is often more cost-effective for standard service applications. For a detailed guide, see our Trunnion mounted VS floating Ball valve comparison.

Our datasheets provide complete technical specifications for each model. Download Datasheet →

Technical Specifications

| Parameter | Specification | Options/Range |

|---|---|---|

| Design Standard | API 6D, API 608 | ASME B16.34 compliant |

| Size Range | 1/2″ to 24″ | DN15 to DN600 |

| Pressure Rating | ANSI Class 150-2500 | PN16 to PN420 |

| Body Material | Carbon Steel, Stainless Steel | WCB, CF8, CF8M, CF3, CF3M |

| Ball Material | Stainless Steel | SS304, SS316, SS316L |

| Seat Material | PTFE, RPTFE, Nylon | Metal seated available |

| End Connection | Flanged | RF, RTJ, FF |

| Operation | Manual, Actuated | Lever, Gear, Pneumatic, Electric |

| Temperature Range | -46°C to +200°C | Extended range available |

| Fire Safe | API 607, API 6FA | Optional certification |

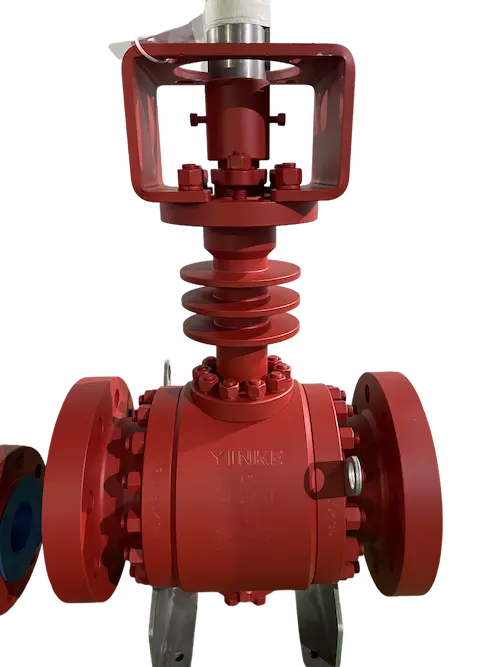

Choosing a Flanged Ball Valve from Yinke

Selecting the correct Flanged Ball Valve requires matching the material, pressure rating, and design to the specific application media and operating conditions. As leading manufacturers, Yinke follows stringent ISO 9001 quality management protocols for every product. This commitment ensures your selected valve delivers optimal performance, safety, and service life.

Our product line includes various configurations to meet diverse industrial needs. The 2 piece flanged ball valve offers a strong balance of robust construction and ease of maintenance. For corrosive environments, our Stainless Steel FLANGED BALL VALVES (SS 304/316) provide superior chemical resistance and durability. We also offer flanged bronze ball valve models for seawater, marine, and municipal water applications where corrosion is a primary concern. The correct flanged ball valve symbol on P&ID drawings is critical for specifying the right component.

- Features materials like Stainless Steel 316 and bronze for specific media compatibility.

- Offers pressure ratings from ANSI Class 150 to 900.

- Provides customizable options for seals, stems, and actuation.

- Includes full material traceability and testing certification upon request.

Flanged ball valves deliver reliable on/off isolation, but for throttling service, butterfly valves or forged steel gate valves are often the better choice. With proper repair and regular maintenance, their service life can be greatly extended. Backed by extensive expertise, our knowledge of flanged ball valves is just as strong as our proven experience with cast steel gate valves.

Our experts can guide you through material selection and all available dimensions. Contact Our Experts →

Technical Resources

Technical Brochure

Complete specifications and selection guide

Sample Drawing

CAD drawings and dimensional details

Ready to Get Started?

Let our experts help you select the perfect flanged ball valve solution for your application.

Why Choose Yinke?

API 6D Certified

Full compliance with international valve standards

25+ Years Experience

Trusted by leading oil & gas companies worldwide

Global Supply Chain

Fast delivery to over 80 countries

Custom Solutions

Tailored valve designs for special requirements

Prefer to talk directly?

Get Your Quote

Fill out the form below and our technical team will contact you within 24 hours with a customized solution.

Your information is secure and will never be shared with third parties.