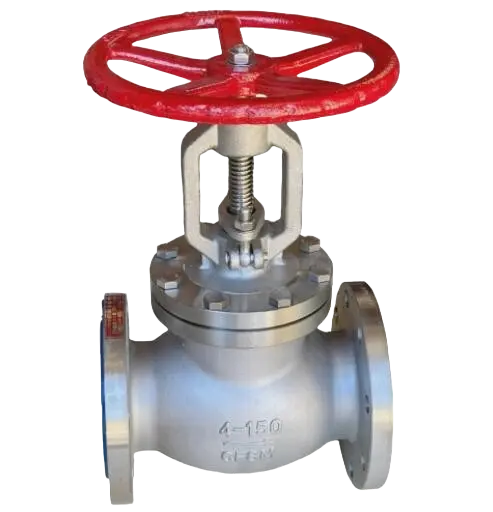

Industrial Globe valve

As a specialty manufacturer, we produce high-performance industrial globe valves in both cast and forged configurations. This provides an optimal balance of structural integrity and cost-efficiency for any project. Our material inventory includes Carbon Steel, Stainless Steel, corrosion-resistant Alloy 20, and a range of exotic alloys suited for severe service conditions. We can supply the right valve for any application, from standard utilities to the most demanding industrial challenges.

Globe Valve Applications, Advantages & Selection

Our Globe Valve Product Range

Cast Carbon Steel Globe Valve

| Size Range | 2″ – 16″ |

|---|---|

| Pressure | ANSI 150# – 2500# |

| Materials | WCB LCB *Other Materials Available |

Cast Stainless & Alloy Globe Valve

| Size Range | 3/4″ – 48″ |

|---|---|

| Pressure | ANSI 150# – 2500# |

| Materials | CF8M Alloy 20 *Other Exotic Materials |

Forged Steel Globe Valve

| Size Range | 1/2″ – 4″ |

|---|---|

| Pressure | ANSI 150# – 2500# |

| Materials | A105N A350-LF2F51 Duplex |

Drawings and Documentation

pdf

CLASS 150

downDownload

pdf

CLASS 300

downDownload

pdf

CLASS 600

downDownload

pdf

CLASS 900

downDownload

pdf

CLASS 1500

downDownload

pdf

CLASS 2500

downDownload

pdf

API 6D

downDownload

book