PSI vs PSIG vs PSIA: Key Differences in Measurement

Psi, or pounds per square inch, is a unit of pressure used to quantify the amount of force applied over a given area. Grasping the distinctions between psi, psig, and psia is vital for professionals and enthusiasts alike who engage in fields where precise pressure measurements are paramount. Each unit offers a distinct insight into pressure measurement, empowering you with the knowledge to make accurate evaluations based on the application at hand.

Definition: What are psi, psig, and psia?

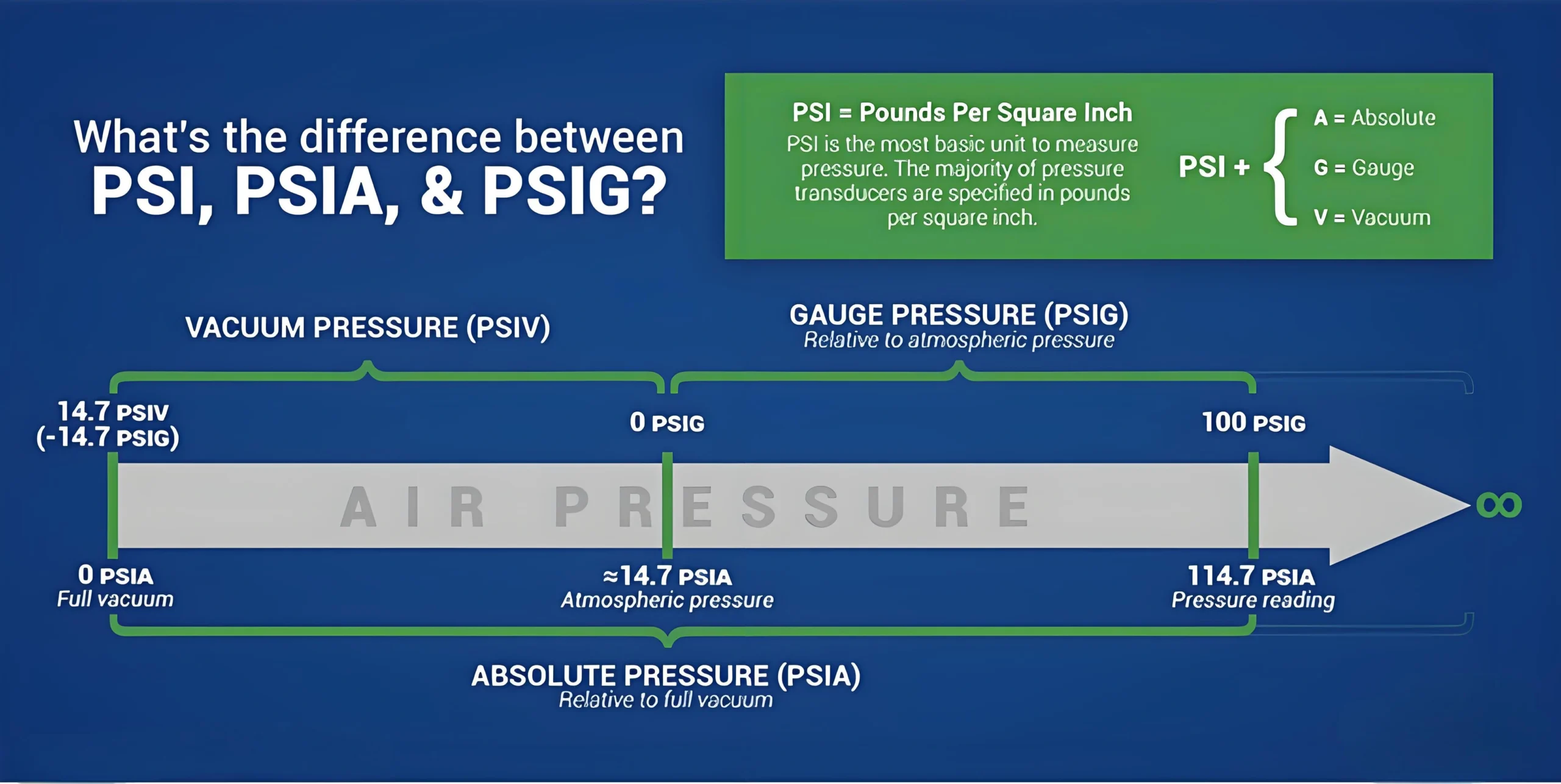

Psi, psig, and psia are all units for measuring pressure in pounds per square inch, but each provides a unique perspective on how force is applied to a surface. Psi measures force per square inch in absolute terms; psig represents gauge pressure, measuring pressure relative to atmospheric conditions; and psia reflects absolute pressure by taking atmospheric variations into account. Recognizing that atmospheric pressure fluctuates with altitude, these differences can have significant practical implications.

psi, psig, and psia are units of pressure measurement, each offering distinct perspectives. While psi is absolute, psig is gauge pressure, and psia accounts for atmospheric pressure variations.

PSI

Pounds per square inch – absolute pressure measurement without atmospheric interference

PSIG

Gauge pressure – measures pressure relative to current atmospheric conditions

PSIA

Absolute pressure – includes both atmospheric pressure and gauge pressure

Practical Example: Automotive Tire Pressure Monitoring

A practical example is automotive tire pressure monitoring. A tire pressure gauge commonly displays psig, indicating the pressure above the atmospheric baseline. If you were to capture the pressure in psia, you would include the atmospheric pressure in your measurement, resulting in a higher value. Furthermore, at high altitudes where atmospheric pressure is lower, the discrepancies between psia and psig become even more pronounced. This comprehensive understanding translates into more precise monitoring and adjustments, which ultimately ensures safety and optimal performance in vehicle handling.

The Principles of Pressure Measurement

When we discuss pressure measurement, it is essential to appreciate the core principles that define readings such as psi, psig, and psia. These terms frequently arise in engineering, automotive, and scientific contexts, and a deeper understanding of them enables more accurate and innovative applications.

Pressure, often measured in pounds per square inch, refers to the force applied perpendicular to an object’s surface per unit area over which that force is distributed. Essentially, psi measures pressure based upon the foundation of a vacuum, devoid of atmospheric interference, which introduces psia.

The transition to psig occurs when we opt for a gauge measure—a relative measurement that compares the current pressure to the ambient atmospheric condition. This aspect is particularly significant when altitudes vary, influencing the pressure readings.

Vacuum Foundation

PSI measures pressure from a complete vacuum baseline

Relative Measurement

PSIG provides pressure measurement relative to atmospheric conditions

Altitude Impact

Altitude variations affect atmospheric pressure and measurement accuracy

It is this distinction that makes psig extraordinarily beneficial in everyday applications, allowing for real-world pressure assessments, while psia enables precision in more detailed engineering evaluations. Embracing these fundamental principles fosters a dynamic approach to pressure measurement, tailored for both everyday utility and advanced technical application.

Ultimately, mastering these principles nurtures innovation and rigorous application across diverse domains. In conclusion, embracing and understanding psi, psig, and psia is key to achieving precision in all pressure-related measurements.

3 examples of practical applications

Pressure systems are integral across various industries. A nuanced grasp of psi, psig, and psia can significantly enhance efficiency and safety in these real-world scenarios:

Automotive Tire Inflation

Ensuring optimal tire pressure is vital in automotive engineering for safety, fuel efficiency, and performance. Mechanics rely on psig measurements to fine-tune tire inflation, skillfully compensating for changes in atmospheric pressure.

In high-altitude settings, where atmospheric pressure is lower, these differences assume even greater importance. On the other hand, high-performance applications, such as race car engineering, might leverage psia for heightened precision.

HVAC Systems

Heating, ventilation, and air conditioning systems depend on psig measurements for accuracy relative to atmospheric conditions, subsequently optimizing energy consumption and operational efficiency.

In specific scenarios where absolute pressure measurements are critical, psia can be utilized to ensure that components can withstand designated pressure thresholds. Altitude variations are also a vital consideration in the design of HVAC systems for diverse building elevations.

Chemical Processing

In chemical engineering, maintaining precise pressure levels is indispensable for reactor safety and efficiency. Here, psia is commonly used to ensure that reactions occur under exact conditions, while psig is frequently employed for routine equipment checks due to its practicality and relation to ambient conditions.

This careful consideration is particularly essential when processes occur at high altitudes, where adjustments must be made to account for lower atmospheric pressure.

By understanding the different contexts where psi, psig, and psia are applied, including altitude considerations, you can confidently select the appropriate measurement standard for the task. Routine checks often benefit from psig readings, while more critical applications may demand the precise insights provided by psia. This awareness highlights the extensive applications of these measurements, each tailored to meet the accuracy and situational needs essential for driving innovation and ensuring reliability in pressure-sensitive environments.

7 tips to deepen your knowledge of psi, psig, and psia

Here are seven strategic steps and illustrative examples designed to help you explore the fascinating world of pressure measurement further:

| Tip | Step | Example |

|---|---|---|

| Enroll in Workshops | Attend specialized workshops that focus on pressure measurement terminology and techniques. | Join local engineering forums or university short courses. |

| Read Technical Journals | Subscribe to engineering and technical magazines publishing the latest research findings. | Access publications such as the Journal of Pressure Vessel Technology. |

| Hands-on Practice | Gain practical experience with pressure measurement tools and devices. | Volunteer or intern with companies in the automotive or HVAC industries. |

| Expert Mentorship | Seek guidance from experienced engineers or professionals in pressure-related fields. | Connect with industry experts through LinkedIn or professional organizations. |

| Online Courses | Utilize online platforms to take in-depth courses on pressure measurement. | Enroll in courses on platforms like Coursera or Udemy. |

| Simulation Software | Use simulation software to model and analyze pressure conditions across various environments. | Explore tools like COMSOL Multiphysics for virtual experiments. |

| Join Industry Groups | Become part of professional groups focused on pressure dynamics and engineering standards. | Join associations such as ASME or the Pressure Institute. |

By applying these tips, you can significantly expand your understanding of psi, psig, and psia. This knowledge empowers you to excel in fields where precise pressure measurement is essential, fostering both professional growth and innovative progress.

Key Terms Related to PSI, PSIG, and PSIA

To thoroughly understand pressure measurements and their implications across different altitudes, it is essential to become familiar with the following foundational terms:

Pressure

The force applied perpendicular to an object’s surface per unit area over which that force is distributed.

Absolute Pressure (PSIA)

The total pressure measured from the absolute zero of pressure, combining atmospheric pressure with gauge pressure, often expressed in pounds per square inch.

Gauge Pressure (PSIG)

The differential pressure measured relative to atmospheric pressure, widely used in daily applications.

Atmospheric Pressure

The pressure exerted by the weight of the atmosphere, which is approximately 14.7 pounds per square inch at sea level. This pressure can vary with altitude, influencing both psia and psig measurements.

Differential Pressure

The difference in pressure between two points in a system; critical for flow calculations and filtration efficiency.

Barometer

An instrument designed to measure atmospheric pressure, often used as a reference for calculating absolute pressure.

Manometer

A device that measures the pressure of gases and vapors, usually yielding gauge pressure readings in pounds per square inch (PSI).

Hydrostatic Pressure

The pressure exerted by a fluid at rest, influenced by gravity and increasing with depth.

Torr

A unit of pressure equivalent to 1/760th of an atmosphere, frequently used in vacuum measurements.

Pascal (Pa)

The SI unit for pressure, defined as one newton per square meter, used extensively in scientific and engineering contexts.

Frequently Asked Questions about PSI vs PSIG vs PSIA

Understanding the subtleties of pressure measurements, including the impact of altitude, can clear up many common queries.

What’s the difference between PSI, PSIG, and PSIA?

PSI, which stands for pounds per square inch, is a general unit for expressing pressure, while PSIG (gauge pressure) represents the pressure measured relative to atmospheric pressure. PSIA (absolute pressure) accounts for both atmospheric pressure and gauge pressure, offering a complete measurement from a vacuum. Atmospheric variations with altitude play an important role in this differentiation.

Why does my gauge show PSIG instead of PSIA?

Gauges generally display PSIG because they measure pressure relative to the current atmospheric conditions, which is more immediately relevant for most everyday applications, especially when considering altitude-induced changes.

How do I convert PSIG to PSIA?

To convert from PSIG to PSIA, simply add the atmospheric pressure (approximately 14.7 psi at sea level) to your gauge reading. Be aware that atmospheric pressure may differ slightly at various altitudes.

Is PSIA used frequently in industries?

PSIA is indispensable in applications where precision is paramount, such as in calibration laboratories and scenarios involving gas laws that require absolute pressure conditions for accurate measurements.

Can atmospheric pressure changes affect my PSIG readings?

Absolutely. While atmospheric pressure fluctuations are typically minor, they can influence PSIG readings since these are measured against the prevailing atmospheric conditions. This effect is particularly noticeable at different altitudes.

Are there tools that measure both gauge and absolute pressure?

Yes, modern dual-function gauges and pressure sensors are designed to toggle between PSIG and PSIA, offering versatile options to meet a variety of technical requirements.

Get In Touch

Have questions about pressure measurement? Contact our expert team for professional consultation.