Socket Weld Ball Valve – Durable Solutions for High-Pressure Applications

High-pressure fluid systems reward careful component choices. When space is tight, pipe sizes are small to medium, and the stakes around leakage are high, a socket weld ball valve can be the difference between effortless operation and chronic downtime. This compact valve style delivers reliable shutoff, repeatable torque, and simplified fabrication for piping that must stay tight under shock, vibration, and thermal cycles.

Request a Quote

Product Categories

Premium Socket Weld Ball Valves for Industrial Excellence

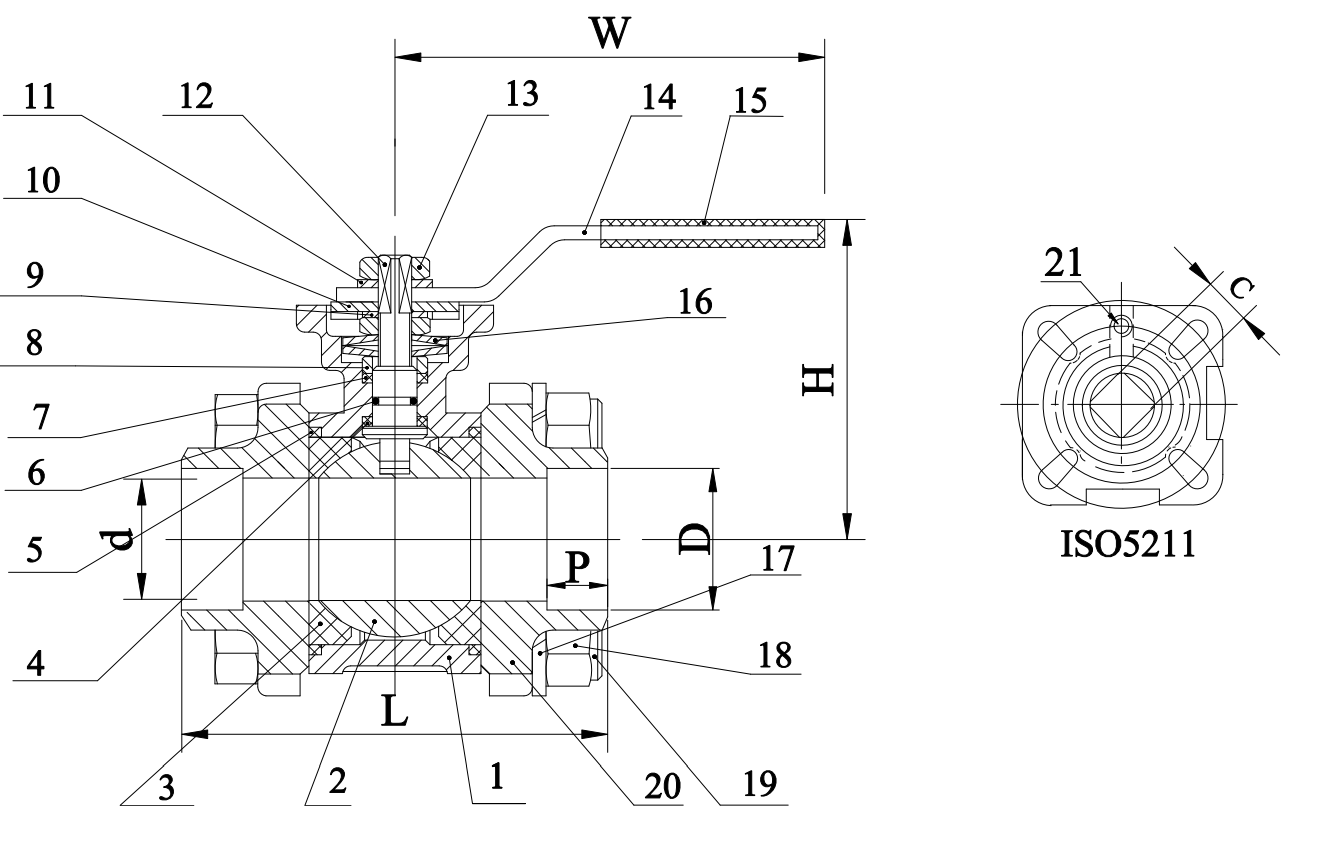

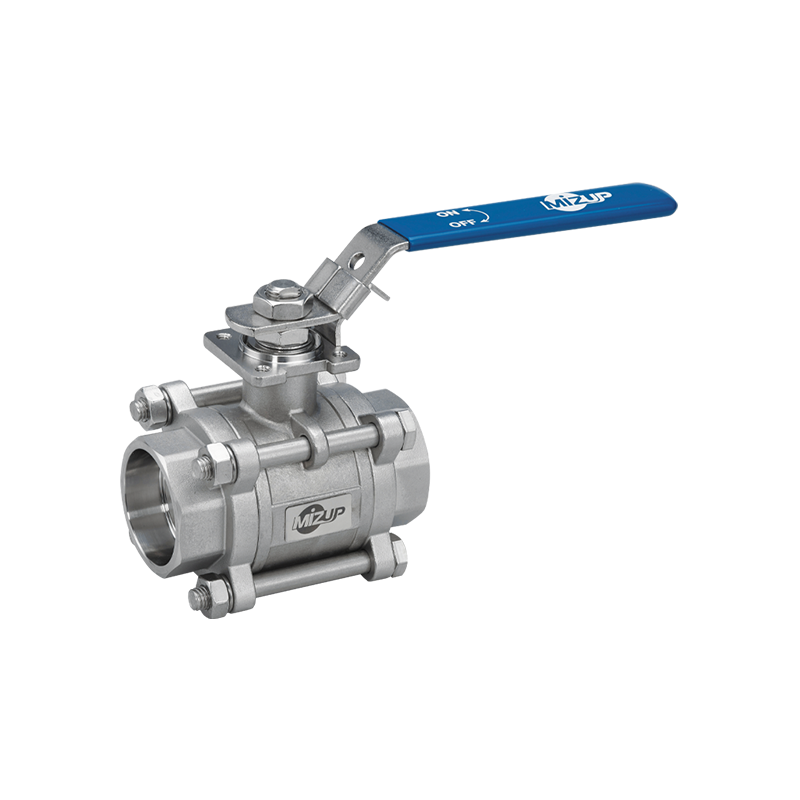

3 Piece Socket Weld Ball Valve

Three-piece construction allows for easy maintenance and seat replacement without removing the valve from the pipeline. Ideal for critical applications requiring maximum serviceability and flexibility.

- Easy maintenance access

- Seat replacement capability

- Superior sealing performance

- Class 800-2500 ratings

Stainless Steel Socket Weld Ball Valve

Forged stainless steel construction (ASTM A182 F304/F316) provides excellent corrosion resistance for chemical processing, pharmaceutical, and marine applications. Superior performance in aggressive media.

- Corrosion resistant

- Chemical compatibility

- High-temperature rated

- Pharmaceutical grade

Carbon Steel Socket Weld Ball Valve

Robust forged carbon steel construction (ASTM A105/A350 LF2) delivers exceptional strength and durability for oil & gas, power generation, and general industrial applications. Cost-effective solution for hydrocarbon service.

- High strength design

- Cost-effective solution

- Oil & gas rated

- Fire-safe options

High-Pressure Socket Weld Ball Valves: A Practical Guide

The goal here is simple: help you specify, install, and maintain socket weld ball valves with confidence. Whether you build skid-mounted equipment, operate process utilities, or manage facility upgrades, a clear picture of design options, standards, and best practices will save time and money.

What is a Socket Weld Ball Valve?

A socket weld ball valve is a quarter-turn isolation valve with pipe ends machined to accept a pipe that is inserted into a socket and then fillet welded. The valve core is a polished spherical ball with a through hole that opens or blocks flow when rotated 90 degrees.

Where does this style shine? Tight spaces, small bore pipe, and dynamic service where vibration or thermal cycling can loosen threads. The socket weld joint delivers a robust, permanent connection that resists leakage without the need for thread sealants.

Key traits that set socket weld ball valves apart include their ability to handle up to 1000 psi pressure:

- High structural integrity thanks to welded joints

- Lower risk of leakage compared to threaded ends

- Compact geometry for skid and panel layouts

- Repeatable quarter-turn operation

- Good fit for high-pressure classes and rugged duty

Where you might pick a different end connection:

- Butt weld ends for larger diameters or full penetration weld requirements

- Threaded ends for temporary installations or frequent disassembly

- Flanged ends for easy removal without cutting pipe

Technical Parameters Overview

| Parameter | Specification | Standard/Range |

|---|---|---|

| Size Range | 1/4″ to 3″ | DN8 – DN80 |

| Pressure Rating | Class 800 – 2500 | Up to 1000 PSI / 69 Bar |

| Temperature Range | -20°F to 750°F | -29°C to 399°C |

| Body Material | Forged Steel | ASTM A105, A350 LF2, A182 F304/F316 |

| Ball Material | SS304/SS316 | Chrome Plated or Stainless Steel |

| Seat Material | PTFE/R-PTFE/PEEK | Virgin or Reinforced PTFE, PEEK for High Temp |

| End Connection | Socket Weld | ASME B16.11 |

| Design Standard | ASME B16.34 | API 608, BS 5351 |

| Fire Safe Design | API 607 / API 6FA | Metal-to-Metal Secondary Sealing |

| Testing Standard | API 598 / ISO 5208 | Shell & Seat Test |

| Operation | Quarter Turn (90°) | Manual, Pneumatic, Electric Actuated |

| Port Type | Full Port / Reduced Port | Standard or Full Bore Options |

Design Features and Construction

Socket weld ball valves are built for strength, serviceability, and clean shutoff. The layout is usually floating-ball with seats that grip the ball under line pressure, creating tight sealing even at low differential pressure.

Forged Steel Body and PTFE Seats

Forged carbon steel or stainless steel bodies dominate this category because of their strength-to-size ratio and excellent pressure retention, making forged steel ball valves a preferred choice for demanding industrial applications. Forgings also handle cyclic stress better than many cast bodies and offer improved grain structure.

Common Construction Options:

- • Body style: one-piece, two-piece, or three-piece

- • Port: full port for minimal pressure drop

- • Seats: PTFE and filled PTFE for general use

- • Stem sealing: PTFE packing, reinforced PTFE

- • Fire-safe features for hydrocarbon service

- • Anti-blowout stem with static grounding

- • ISO 5211 mounting pads for actuation

Typical Body & Trim Materials:

- • ASTM A105 or A350 LF2 carbon steel

- • ASTM A182 F304 or F316 stainless steel

- • Duplex or nickel alloys for severe service

- • Chrome plated balls and stems

- • PEEK seats for higher temperature

- • Graphite packing for fire-safe design

- • Devlon, UHMWPE specialty polymers

Fire-Safe and Blow-Out Proof Design

Fire-safe valves are common in hydrocarbon systems. The concept is simple. If soft seats and seals degrade in a fire, a metal-to-metal sealing path limits external leakage to protect personnel and equipment. This is validated by published fire test protocols and acceptance criteria.

Fire-Safe Features to Look For:

- ✓ A secondary metal seat that engages the ball after polymer seats are compromised

- ✓ Graphite stem packing and body seals that maintain tightness at high temperature

- ✓ Anti-static features to maintain electrical continuity across the ball and body

- ✓ Blow-out proof stem that loads from the inside and is retained even if the packing gland loosens

Seat and Packing Selection Guide

| Component | Common Material | Typical Temp Range | Strengths | Watchouts |

|---|---|---|---|---|

| Seats | PTFE | -20 to 400°F | Low friction, broad chemical range | Cold flow at high pressure, steam limits |

| Seats | R-PTFE | -20 to 450°F | Better wear and extrusion resistance | Some media compatibility changes |

| Seats | PEEK | -20 to 500°F | High strength, good at pressure drop | Cost, chemical limits with strong acids |

| Packing | PTFE | -20 to 400°F | Low friction, clean service | Not ideal for high temp hydrocarbon fires |

| Packing | Graphite | -20 to 750°F+ | Fire resistance, high temp duty | Requires proper gland torque to seal |

Values are representative. Always check the vendor’s datasheet for tested limits.

Industrial Applications

Oil & Gas

- • Wellhead skids

- • Separators

- • LACT units

- • Gas compression

- • Fuel gas systems

- • Methanol injection

Chemical Processing

- • Solvents handling

- • Light hydrocarbons

- • Polymer production

- • General chemical duty

- • Batch processing

- • Reactor systems

Power Generation

- • Condensate systems

- • Cooling water headers

- • Nitrogen lines

- • Hydrogen service

- • Boiler feed loops

- • Instrument air

Industrial Gases

- • Oxygen service

- • Cryogenic applications

- • High-purity systems

- • Gas distribution

- • Cylinder manifolds

- • Specialty gases

Pulp & Paper

- • Chemical recovery

- • Bleaching systems

- • Steam distribution

- • Process water

- • Black liquor

- • Waste treatment

Marine & Mining

- • Seawater systems

- • Ballast control

- • Hydraulic systems

- • Slurry transport

- • Process circuits

- • Dewatering lines

Installation and Maintenance Guidelines

A socket weld ball valve is only as good as its welds, alignment, and protection from heat during installation. Follow a stepwise approach to avoid seat damage and misalignment.

Pre-Install Checks

- • Inspect bore, ball, and seats for debris

- • Verify material grade stamps and MTRs

- • Confirm pressure class and size

- • Cycle valve for smooth operation

- • Check valve directionality if applicable

Welding Best Practices

- • Maintain proper socket depth and gap

- • Keep valve open during welding

- • Shield body with heat sinks

- • Control interpass temperature

- • Use proper weld sequencing

Preventive Maintenance Tips

- Operate the valve through a full cycle on a regular interval to keep seats clean and prevent sticking

- Retorque gland nuts in small increments if stem seepage appears, following the manufacturer’s guidance

- Replace packing and seats when torque rises steadily or leak rates increase, particularly in industrial applications where performance is critical and pressures exceed 1000 psi

- Keep actuation hardware clean, dry, and lubricated where specified

- Document all service actions to track trends in torque and leakage

Specifications and Standards Compliance

Decision quality improves when you anchor it to recognized standards and clear ratings. Socket weld ball valves, including forged steel ball valves, intersect with a handful of core documents and pressure-temperature tables that define limits you can trust.

Design Standards

- ASME B16.11: Socket weld end dimensions

- ASME B16.34: Valve design and PT ratings

- API 607: Fire-safe performance testing

- API 598: Pressure test methods

- ISO 5208: Seat leakage classes

Material Standards

- ASTM A105: Carbon steel forgings

- ASTM A350 LF2: Low-temp carbon steel

- ASTM A182: Stainless steel forgings

- NACE MR0175: Sour service materials

- ISO 5211: Actuation interface

ASME B16.34 and API 607 Compliance

ASME B16.34 is the backbone of pressure-boundary integrity for steel valves. It covers design rules, body wall thickness, and pressure-temperature ratings based on material groupings. Compliance signals that the valve has enough metal at the right places and that the design meets a rational safety margin.

API 607 confirms that a fire-safe valve will hold up under a controlled burn and then reseal. This standard increases confidence when the system handles flammable media. For many projects, the purchasing spec will call out both B16.34 and API 607, along with a defined pressure class and end standard like B16.11.

Frequently Asked Questions

What is the difference between socket weld and threaded ends?

Socket weld ends are fillet welded to the pipe for a permanent joint. Threaded ends assemble with NPT or BSP threads and a sealant. Socket weld joints resist vibration and thermal cycling better and offer lower leak risk.

Can I weld with the seats installed?

Many forged two-piece valves, including forged steel ball valves, are designed to be welded with seats in place if you control interpass temperature and apply heat sinks. Some designs specify disassembly or extended weld ends. Follow the manufacturer’s weld instructions.

Are socket weld ball valves suitable for steam?

Only when the valve is built for it. Graphite packing and high-temp seats are recommended. PTFE-only designs struggle with saturated or superheated steam and may lose tightness.

What does fire-safe mean?

A fire-safe design can limit external leakage during and after a fire event. Polymer seats and seals may degrade, but the valve uses a secondary metal-to-metal path and graphite seals to maintain reasonable tightness. Look for API 607 certification.

Should I choose full port or standard port?

Full port minimizes pressure drop and helps with pigging in some systems. Standard port offers a smaller body and often lower cost. For viscous fluids, slurries, or measurement lines where pressure drop matters, full port is the safer pick.

How do I size the pressure class?

Use the system’s design pressure and temperature along with ASME B16.34 tables for the selected material. Then confirm seat and packing limits. Add margin for transients like water hammer or compressor surge.

Can I automate a socket weld ball valve?

Yes. Many models include an ISO 5211 mounting pad. Choose a quarter-turn pneumatic or electric actuator sized for the maximum required torque at design pressure, with travel stops and feedback per your control scheme.

How often should a valve be cycled if it stays normally closed?

A monthly manual or automated cycle is a good baseline for clean service. Dirty or particulate-laden media may require more frequent cycling to prevent seat imprinting and sticking.

Technical Documentation

Download our comprehensive technical resources to help with your valve selection and specification process.

Request a Quote

Get expert assistance with your socket weld ball valve requirements. Our technical team is ready to help with sizing, material selection, and application guidance.