What Is a Ball Valve?

An Engineer’s Practical Guide

As a mechanical engineer with over 30 years of hands-on experience in industrial fluid systems, I’ve specified, installed, and seen the failure of thousands of valves. Among them all, the humble ball valve remains one of the most reliable and misunderstood components.

Its genius lies in its simplicity, but choosing the right one—and avoiding the wrong one—can be the difference between a system that runs for decades and one that fails catastrophically.

This guide covers:

- The Core Anatomy: A visual breakdown of how a ball valve really works.

- Key Types Demystified: A simple decision-making framework to choose between full port, three-piece, trunnion-mounted, and more.

- Material Selection Pro-Tips: Why picking brass over stainless steel (or vice versa) can be a costly mistake.

- Real-World Applications & Common Pitfalls: Lessons learned from actual industrial and residential projects.

Whether you’re designing a new system or just trying to shut off the water under your sink, my goal is to give you the confidence to master this essential component.

What is a Ball Valve?

A ball valve is a quarter-turn shut-off valve that controls the flow of a fluid or gas using a rotating ball with a hole (the bore) through it. A 90-degree turn of the handle aligns the bore with the flow path, allowing the medium to pass (open position). Another 90-degree turn places the solid side of the ball against the flow, creating a tight seal and stopping it (closed position).

This simple operation makes ball valves incredibly easy to use and allows for immediate shut-off, a critical feature in emergency situations. They are industry workhorses, known for their durability, tight sealing, and reliability, even after long periods without use.

Key Components of a Ball Valve

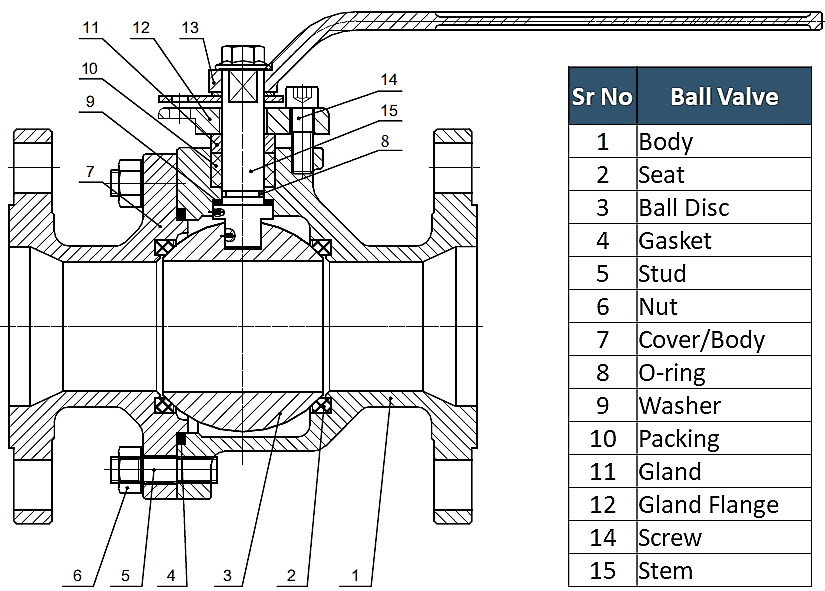

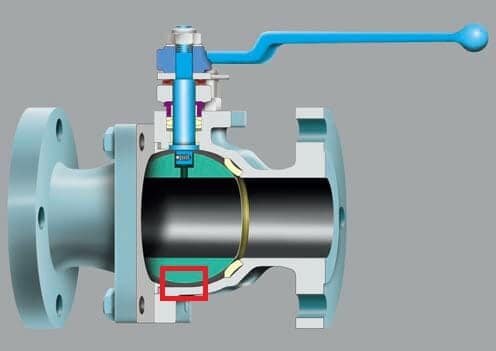

Cross-sectional diagram of a standard ball valve showing all key components

Before we list the parts, let’s visualize them. The diagram above shows how each component fits together to create a robust seal. Now, let’s break down each part’s role.

Valve Body (or Housing)

The main exterior structure that contains all internal components and connects to the pipeline. It’s typically made from durable materials like stainless steel, brass, or PVC.

Ball

The sphere with a hole (bore) through the middle that rotates to control flow. It is often chrome-plated for durability and wear resistance.

Stem

The shaft connecting the external handle to the ball. Turning the handle rotates the stem, which in turn rotates the ball.

Seats

Two rings, typically made of a soft material like PTFE (Teflon), that sit between the ball and the valve body. They create the primary seal and support the ball.

Seals (or Packing)

O-rings and packings around the stem that prevent the fluid or gas from leaking out of the valve body.

Handle (or Actuator)

The external lever used to turn the stem. For automated systems, an electric, pneumatic, or hydraulic actuator replaces the manual handle.

Bonnet

On some designs, this covers the opening in the valve body and houses the stem and packing.

End Caps

The parts that connect the valve body to the pipeline, available in threaded, flanged, or welded types.

How Ball Valves Work: The Quarter-Turn Principle

The operating principle is efficient and straightforward. The handle’s position provides a clear visual indicator of the valve’s state.

Open Position

The handle is parallel to the pipe. The ball’s bore is aligned with the pipeline, allowing fluid or gas to flow with minimal restriction.

Closed Position

The handle is perpendicular to the pipe. The solid surface of the ball blocks the pipe, stopping the flow completely.

Types of Ball Valves: Making the Right Choice

Understanding the variations is key to selecting the right valve. They are categorized by bore size, port configuration, body construction, and ball mounting.

Bore Size: Full Port vs. Reduced Port

Full Port (Full Bore)

The bore diameter is the same as the pipe’s inner diameter. This means zero flow restriction and a very low pressure drop. They are essential for pipelines that require cleaning via “pigging.”

Reduced Port (Standard Bore)

The bore is smaller than the pipe’s diameter. This creates a slight flow restriction but makes the valve more compact and less expensive.

Port Configuration: Two-Way, Three-Way, and Multi-Port

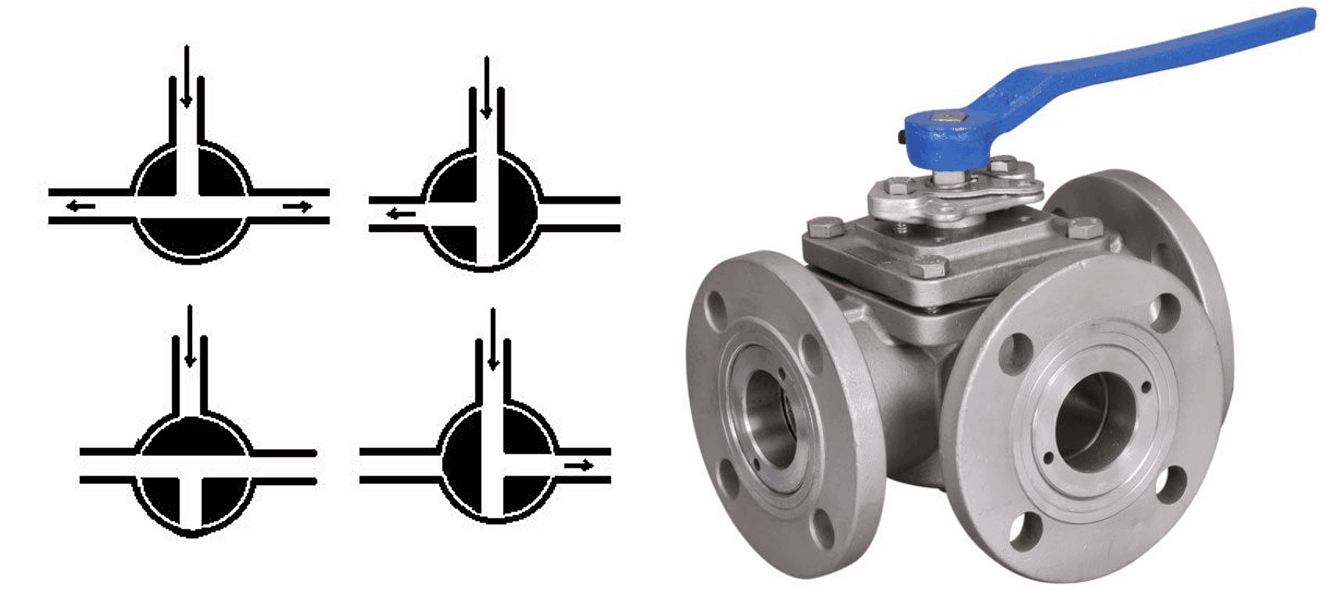

Three-way ball valve configurations showing L-Port and T-Port options

Two-Way

The standard on-off valve with one inlet and one outlet.

Three-Way

Used for diverting or mixing flows, with three ports.

- L-Port: Can divert flow from one inlet to one of two outlets, or shut off flow completely.

- T-Port: More versatile; can mix two inlets to one outlet, divert one inlet to two outlets, or pass flow straight through.

Body Construction

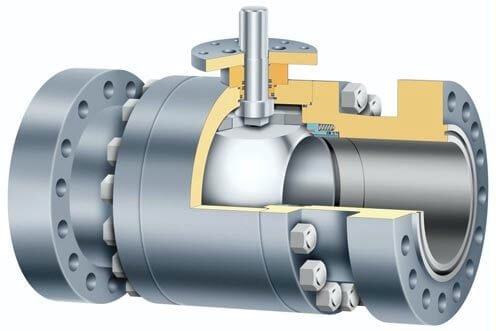

Three-piece trunnion mounted ball valve showing modular construction

One-Piece

A single cast body. Inexpensive but cannot be repaired; considered a “throwaway” valve.

Two-Piece

Body made of two joined pieces. Can be disassembled for maintenance but usually must be removed from the pipeline.

Three-Piece

A main body and two end caps. The body can be swung out for repair without disturbing the pipe connections, making it ideal for systems requiring frequent servicing.

Ball Mounting: Floating vs. Trunnion-Mounted

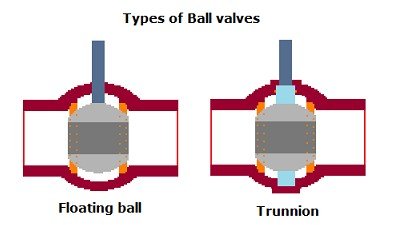

Comparison between floating ball and trunnion-mounted ball valve designs

Floating Ball

The most common design. The ball is held by the seats, and upstream pressure pushes it against the downstream seat to create a seal. Used for smaller and lower-pressure applications.

Trunnion-Mounted Ball

The ball is supported by an additional shaft (trunnion) at the bottom. This support absorbs system pressure, reducing seat load and making the valve easier to turn. Essential for large, high-pressure applications.

Quick Selection Guide: Which Ball Valve is Right for You?

Feeling overwhelmed? Use this table to guide your decision.

| Feature / Type | One-Piece | Two-Piece | Three-Piece |

|---|---|---|---|

| Cost | Lowest | Moderate | Highest |

| Maintainability | Not Repairable (“Throwaway”) | Repairable (must be removed) | Easiest to Repair (in-line) |

| Best For | Low-cost, non-critical uses (e.g., basic irrigation) | General purpose plumbing & industrial use | Critical processes requiring frequent maintenance (e.g., chemical plants) |

Pro Tip:

For most serious home plumbing, like a main shutoff, a two-piece full-port brass valve is a reliable and cost-effective choice. In a factory setting, the long-term maintenance savings of a three-piece design often justifies the higher initial cost.

Materials of Construction: A Critical Decision

Material choice is where costly mistakes are often made. The selection depends on the fluid, temperature, pressure, and environment.

Comparison of different ball valve materials and their applications

Stainless Steel

Excellent corrosion resistance and durability. The go-to for chemical processing, water treatment, and food/beverage industries.

Brass

Affordable and corrosion-resistant for non-corrosive media like water, oil, and air. The standard for residential plumbing.

PVC (Polyvinyl Chloride)

Lightweight and corrosion-resistant plastic for low-pressure, low-temperature water applications like irrigation.

Carbon Steel

Strong and durable for high-pressure, high-temperature service, especially in the oil and gas industry.

Seat materials like PTFE (Teflon) are crucial for creating the seal. The right combination of body and seat material is vital for valve longevity.

Advantages and Disadvantages

Advantages

Excellent Shutoff

Provides a tight, reliable, “bubble-tight” seal.

Quick Operation

The quarter-turn design is fast and simple.

Durability and Reliability

Long service life with minimal maintenance.

Versatility

Available in a huge range of sizes, materials, and designs.

Low Pressure Drop

Full-port designs offer very little resistance to flow.

Disadvantages

Poor Throttling Characteristics

I’ve seen countless valve seats destroyed by technicians trying to use a ball valve to regulate flow. They are designed for on-off service only. Partial opening causes high-velocity flow that erodes the seats and ball, leading to failure.

Fluid Trapping

In the closed position, a small amount of liquid can be trapped in the body cavity. If this liquid freezes and expands (like water), it can crack the valve body. Vented ball valves are required for such applications.

Applications of Ball Valves

From industrial plants to your own home, ball valves are everywhere.

Ball valves in industrial applications including oil, gas, and chemical processing

Industrial Uses

Oil and Gas

Pipelines, processing plants, and storage facilities.

Chemical Processing

Handling aggressive chemicals with stainless steel or specialty alloy valves.

Water Treatment

Municipal and industrial water systems.

Food and Beverage

Sanitary stainless steel valves for controlling liquid flow.

Everyday Uses

Plumbing

Main water shutoffs for a house; isolation valves for toilets, sinks, and water heaters.

Appliances

Water supply lines for washing machines and dishwashers.

Outdoor Hoses

Connection points for garden hoses.

Maintenance and Care

While low-maintenance, a few checks ensure long-term reliability.

Inspection

Regularly check for leaks around the stem packing and end connections.

Operation

At least twice a year, cycle the valve from open to closed and back. This prevents mineral buildup from seizing the ball, a common issue in hard water areas.

Cleaning

In systems with sediment, a three-piece valve makes cleaning far easier.

Troubleshooting

Leaks often point to worn seats or seals. On two-piece and three-piece valves, these can often be replaced with a simple repair kit.

The Future of Flow Control

The ball valve is a mature technology, but innovation continues. We’re seeing smarter valves with integrated sensors to monitor flow and pressure, and new materials for more extreme service conditions. As industrial automation grows, the ball valve’s role as a reliable, remotely-operated component is more critical than ever.

Get Expert Advice

Have questions about ball valve selection for your specific application? Contact our engineering team for professional guidance.