What is a Check Valve and How it Works

A comprehensive guide to understanding check valves – the essential components that ensure unidirectional fluid flow in your systems

A check valve is a mechanical device that guarantees fluid flows in one direction while preventing reverse movement. It automatically closes when the flow reverses, ensuring system stability, efficient fluid dynamics, and overall integrity without manual intervention. Understanding check valves aids in selecting appropriate valves for different applications and protecting piping systems with precise flow control.

Definition: What is a Check Valve?

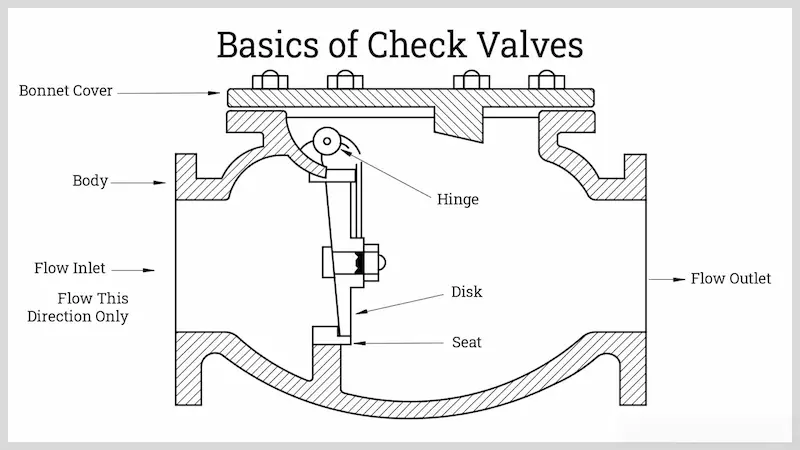

Figure 1: Check valve cross-section diagram showing internal components and flow direction

A check valve allows liquids or gases to flow solely in one direction. Like an automatic gate, it includes a closure mechanism that reacts to changes in fluid pressure. Operating on the principle of a pressure differential, check valves provide flow regulation without manual adjustments.

“A check valve is a device that allows fluid flow in one direction only. It prevents backflow automatically when the pressure reverses.”

Imagine a check valve as a security gate for fluid systems. In a domestic water pump system, it sends water from the pump to the home without allowing it to return to the source. Its automatic closure maintains water pressure, limits contamination risk, and promotes efficient fluid dynamics.

The Principles of Check Valve Operation

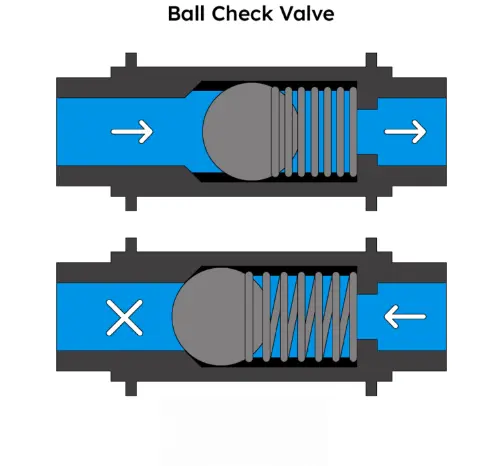

Figure 2: Ball check valve components showing the ball mechanism for flow control

Check valves secure unidirectional flow across various media and applications. They operate based on a pressure difference: the valve opens when upstream fluid pressure exceeds downstream pressure and closes when the reverse occurs. This self-regulating mechanism provides a well-defined flow path that protects the system and preserves safety.

A typical check valve includes a disc, wafer, or ball that moves to open or block the flow. Ball check valves, for example, offer reliability in both liquids and gases. When the cracking pressure (the minimum upstream pressure) is reached, the valve opens for uninterrupted flow. When the downstream pressure is higher, the valve quickly closes, ensuring precise flow control and preventing reverse movement. Constructed from durable materials such as stainless steel, brass, or PVC, these valves perform reliably in varying conditions and contribute to energy savings.

Examples of Check Valve Applications

Check valves are essential in many industries, offering reliable flow regulation and system dependability.

Water Supply Systems:

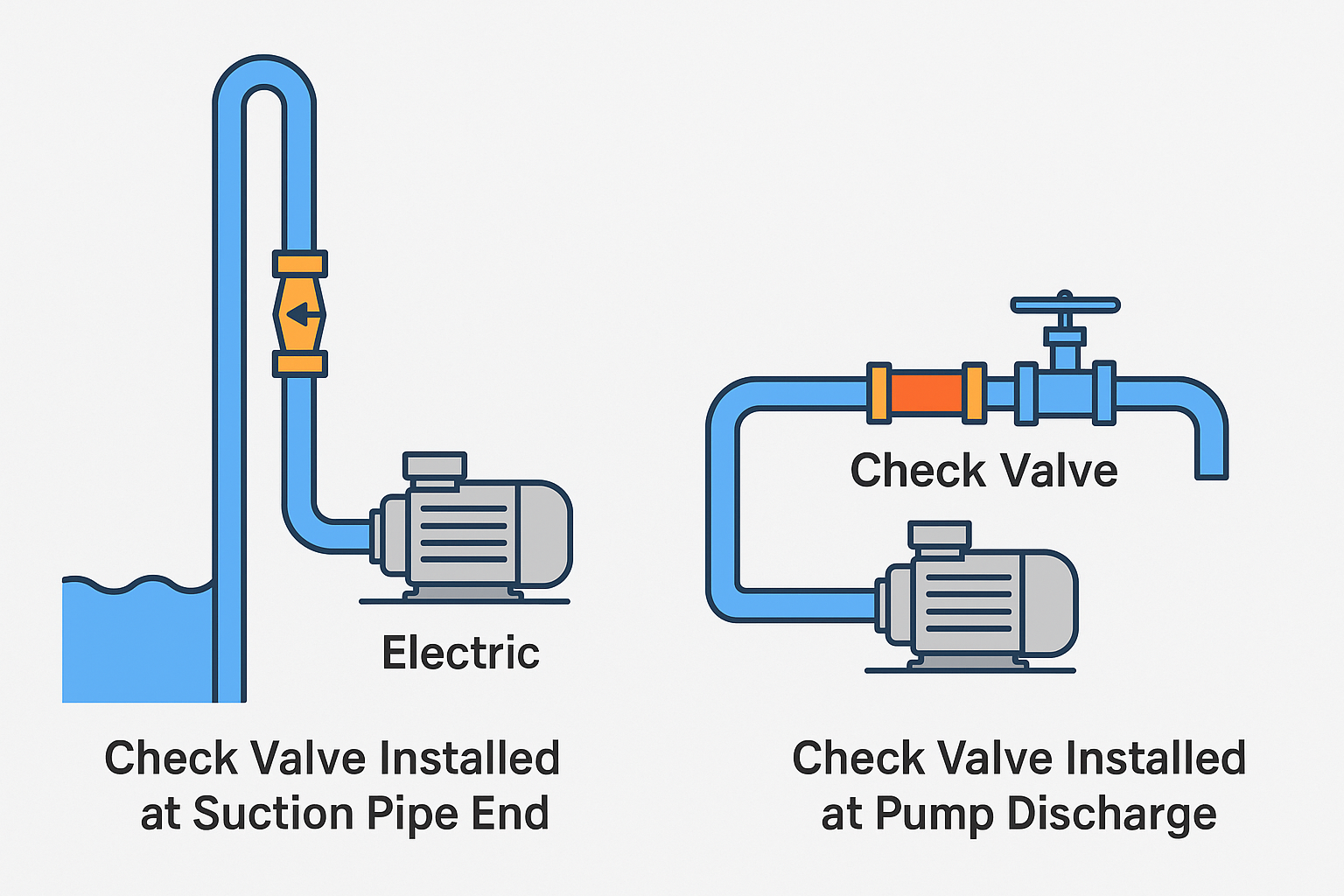

Check valve installation in pump system

In residential and commercial piping, check valves prevent backflow, ensuring water reaches all parts of the system with consistent pressure and quality.

Oil and Gas Pipelines:

They facilitate the safe transport of hydrocarbons by halting reverse flow, reducing pressure surges, and maintaining system integrity.

HVAC Systems:

Check valve application in HVAC systems

They secure the direction of airflow and refrigerant movement, ensuring stable temperature regulation, lower energy costs, and efficient operation.

Regular preventive maintenance is necessary to address issues such as variations in cracking pressure or sediment buildup, preserving a valve’s efficient performance.

7 Tips for Mastering Check Valve Applications

Improve your application of check valves with these practical tips:

| Tip | Step | Example |

|---|---|---|

| Conduct Regular Inspections | Schedule periodic assessments to check for wear and tear. | Inspect HVAC system valves quarterly to maintain optimal airflow. |

| Choose Suitable Materials | Select materials based on the fluid type and environmental conditions. | Use stainless steel check valves in corrosive conditions for durability. |

| Use Advanced Monitoring Techniques | Employ flow sensors and smart diagnostics for real-time performance data. | Integrate IoT technology to monitor valve operations in industrial pipelines. |

| Stay Updated on Industry Standards | Review and follow current regulations and standards. | Subscribe to valve manufacturer updates and newsletters for the latest information. |

| Increase Technical Knowledge Through Training | Participate in specialized workshops and training sessions. | Attend webinars by industry experts on advanced fluid control mechanisms. |

| Collaborate with Industry Peers | Network with professionals to share insights on valve performance and fluid dynamics. | Join professional forums and discussion groups dedicated to piping systems. |

| Adopt Innovative Technologies | Monitor emerging technologies that improve valve performance and energy efficiency. | Use digital twins to simulate and optimize fluid control systems in complex networks. |

These practical tips allow professionals to optimize the use of check valves, drive technological improvements, and maintain system safety and efficiency.

Key Terms Related to Check Valves

Familiarize yourself with these key terms to build a solid foundation for mastering check valve technology:

Cracking Pressure:

The minimum upstream pressure required to open the valve and start fluid flow.

Backflow:

The unintended reverse movement of fluid in a system, which check valves are designed to block.

Lift Check Valve:

A check valve where the disc lifts from the seat as fluid flows upward, providing controlled flow.

Swing Check Valve:

Featuring a swinging disc, this valve manages pressure effectively in larger systems.

Dual Plate Check Valve:

Uses two hinged plates to reduce water hammer and ensure quick closure.

Water Hammer:

A pressure surge caused by sudden changes in fluid movement when flow stops abruptly.

Pressure Drop:

The reduction in pressure across the valve, affecting overall system efficiency.

Non-slam Check Valve:

Closes rapidly and quietly to prevent water hammer and reduce noise.

Retainerless Check Valve:

Designed without an internal retainer, reducing potential leak paths.

Automatic Closure:

The valve’s ability to shut by itself upon detecting reverse flow, ensuring unidirectional control.

Installation Best Practices and Common Mistakes

Figure 3: Proper check valve installation considerations and positioning guidelines

Proper installation is vital for check valve performance, durability, and reliability. Follow these guidelines for smooth operation and safety:

Best Practices

- Follow Flow Direction: Install the valve according to the indicated arrow to maintain proper flow control and automatic closure.

- Correct Positioning: Place check valves as near as possible to the equipment they protect, such as pumps or compressors, to reduce reverse flow risks.

- Avoid Vertical Downflow: Most check valves are best used in horizontal or upward flows; a vertical downflow may stress the mechanism.

- Allow Maintenance Access: Provide enough space around the valve for inspections, cleaning, or replacement.

Common Mistakes

Do not overtighten connections, use incompatible materials, or skip flushing the system before installation, as these errors can introduce debris and impair function.

Maintenance, Troubleshooting, and Failure Modes

Routine maintenance and troubleshooting ensure reliable operation and extend a check valve’s lifespan:

Maintenance Tasks

- Inspection: Regularly check for leaks, abnormal sounds, or reduced flow, which may signal wear, debris accumulation, or malfunction.

- Cleaning: Remove debris that may hinder sealing and flow.

- Replacement: Replace worn or damaged parts such as seals, springs, or the disc to maintain system performance.

Common Failure Modes

Water Hammer:

Occurs when a valve shuts too quickly, causing pressure surges; using slow-closing or silent check valves can reduce this risk.

Sticking or Jamming:

Often caused by debris or corrosion; routine cleaning and preventive maintenance are necessary.

Reverse Flow:

Indicates a malfunction or improper installation, leading to compromised safety and flow integrity.

Selection Criteria for Different Applications

Choosing the right check valve requires careful consideration of factors that influence fluid dynamics, system durability, and energy consumption:

| Application | Recommended Type | Key Considerations |

|---|---|---|

| Water Systems | Swing, Ball, Silent | Target low pressure drop, quiet operation, and robust automatic closure to block backflow. |

| Industrial Fluids | Lift, Piston, Dual Plate | Consider chemical compatibility, durability, and precise pressure management for effective regulation. |

| Gases | Spring-loaded, Poppet | Ensure tight sealing, low leakage, and reliable direction control in gas applications. |

| Slurries | Ball, Diaphragm | Choose valves that handle clogging and abrasion while delivering smooth flow. |

Material Compatibility

Verify that the materials used (stainless steel, brass, or plastic) suit the fluid to prevent corrosion and degradation.

Pressure and Temperature

Select valves with ratings that exceed system requirements for secure performance.

Cost vs. Performance

Balance the initial investment, maintenance costs, and long-term durability to achieve energy efficiency and sustained process excellence.

Check Valve Symbols and Standards

Knowing engineering symbols and standards is essential for system design and quality assurance:

Symbols

A check valve is typically shown as a line with an arrow indicating the flow direction, paired with a perpendicular line that represents its one-way function.

Standards

Familiar standards include ASME B16.34, API 594, and ISO 5208, which cover design, testing, and performance specifications. A diagram of these symbols and a summary of each standard assist engineers in interpreting technical drawings for compatibility and reliability.

Real-World Case Studies or Application Examples

Case Study 1: Municipal Water Supply

In a city water system, swing check valves installed at pump outlets prevent backflow during power outages. This design guards pumps from reverse rotation, reduces maintenance costs, and maintains stable fluid dynamics over time.

Case Study 2: Industrial Chemical Processing

A chemical plant chose corrosion-resistant ball check valves for aggressive media areas. This decision maintained precise flow regulation, minimized downtime from valve failure, and ensured reliable chemical processing.

Case Study 3: Domestic Plumbing

Homeowners use silent check valves in sump pump discharge lines to eliminate water hammer and lower noise. The dependable automatic closure enhances comfort, energy efficiency, and system longevity.

Advanced Types and Innovations

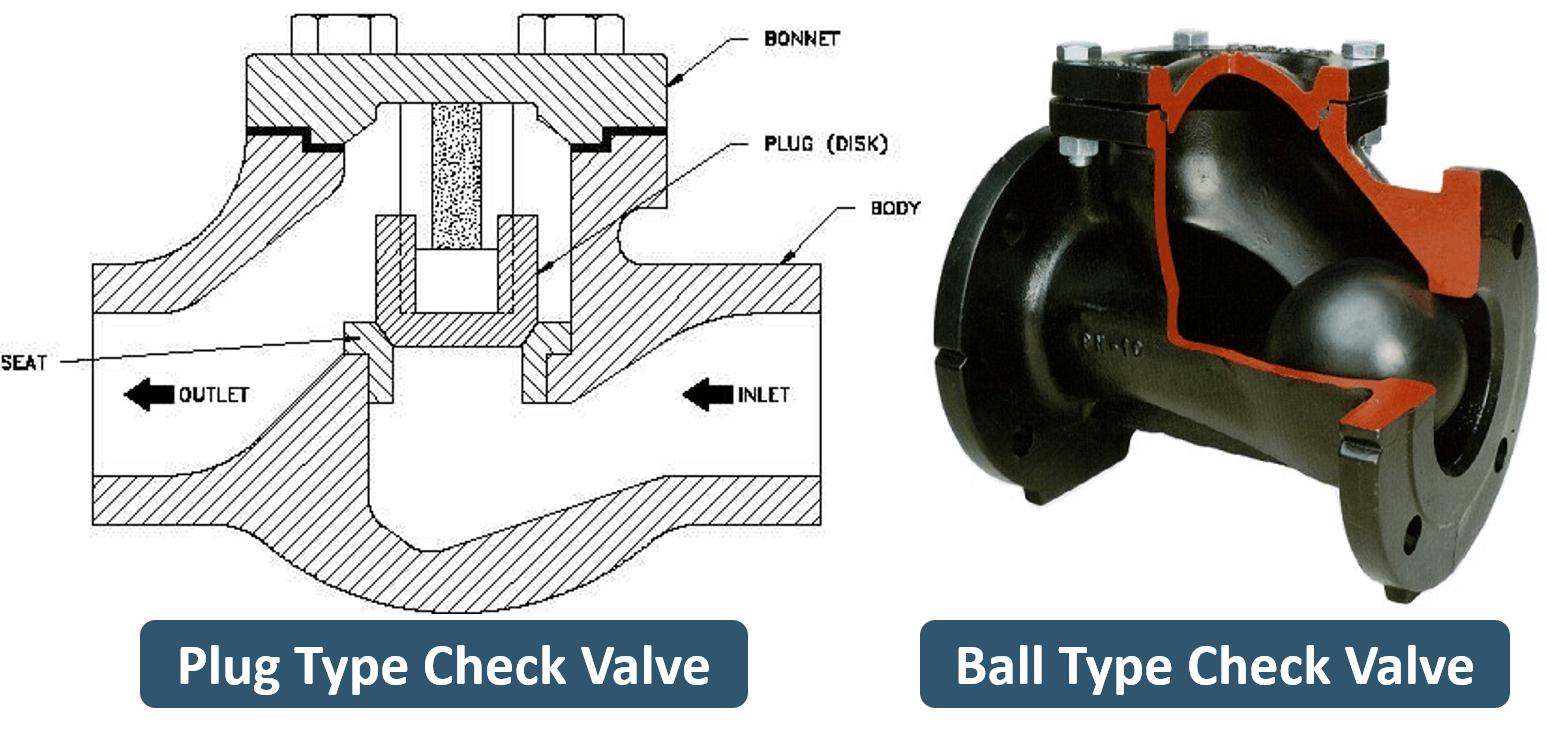

Figure 4: Various advanced check valve types – lift, ball, and plug configurations

Modern check valve designs continue to address industry challenges with technological advances:

Silent (Non-Slam) Check Valves

These valves close rapidly and quietly, reducing water hammer and saving energy in high-velocity systems.

Double-Door (Dual Plate) Check Valves

Compact and lightweight, they suit large-diameter pipelines where space is limited and precise flow control is needed.

Axial Flow Check Valves

With reduced pressure drop and quick response times, they are ideal for industries like oil, gas, or power generation where consistent fluid dynamics are vital.

These innovations allow for choices that meet current standards and prepare systems for future demands in fluid control and mechanical performance.

Environmental and Energy Efficiency Considerations

Choosing and maintaining the right check valve has a positive impact on sustainability and energy conservation:

Reduced Energy Loss

Properly sized and maintained valves minimize pressure drops, lowering pump energy consumption and optimizing fluid dynamics.

Leak Prevention

Reliable valves stop unwanted backflow, decreasing product loss and environmental contamination while supporting energy-saving efforts.

Sustainable Materials

Valves made from recyclable or long-lasting materials support environmental goals and extend system durability.

Evaluating lifecycle costs and environmental impacts during valve selection helps achieve energy efficiency and high system performance.

Frequently Asked Questions about What is a Check Valve and How it Works

How does a check valve prevent backflow?

Check valves—whether ball or swing types—allow fluid to flow one way by automatically closing when reverse pressure is detected. This regulation protects pressure consistency throughout the network.

Why might a check valve fail to function?

Failure can occur due to improper installation, wear over time, debris buildup, or corrosion. Regular preventive maintenance and inspections help keep the valve working properly.

Can check valves be used with gases?

Yes, check valves work effectively with both liquids and gases. Verify material compatibility and pressure ratings to ensure safe operation in gas applications.

What is the minimum pressure needed to open a check valve?

The cracking pressure is the minimum upstream pressure required to overcome the valve seal and allow flow. This value varies by design and application.

Can check valves reduce water hammer effects?

Yes, silent or non-slam check valves close quickly and quietly, significantly reducing pressure surges and preventing water hammer.

How should one select the right check valve type?

Consider factors such as flow rates, fluid type, operating pressure, temperature, and system design. The chosen valve must meet the specific requirements for safe, efficient, and reliable performance.

Contact Us

Have questions about check valves or need expert consultation for your specific application? Get in touch with our technical team.

Contact Form

Our technical experts will respond within 24 hours